Inaccurate gas readings, unstable flow, or pump failures can ruin even the best analyzer designs. These issues often stem from overlooked sample pumps—components many engineers treat as generic. But using the wrong micro pump can compromise your entire sensing system. By understanding what truly defines a high-performance sample pump, especially in compact or OEM gas analyzers, you can dramatically improve your device’s stability, accuracy, and lifespan.

A good sample pump for gas analyzers ensures consistent flow, reliable vacuum, low pulsation, and chemical compatibility, all while fitting compact form factors. It should be oil-free, long-lasting, and easy to integrate with modern control systems like PWM or analog input. Diaphragm micro pumps are often preferred for their clean operation, low noise, and high customizability.

Looking to avoid common integration pitfalls and select the right pump the first time? Read on—we’ll break it all down for you.

What Is the Function of a Sample Pump in a Gas Analyzer?

A sample pump is responsible for extracting, transferring, and delivering a gas sample to the sensor inside the analyzer. The goal is to provide a stable, uncontaminated, and pressure-controlled gas flow that represents the environment being monitored.

Gas analyzers come in many forms—NDIR, electrochemical, PID, TCD, GC/MS—and they all rely on precise gas input. Without a reliable pump, you face issues like:

- Delayed readings due to poor suction

- Sensor drift caused by unstable pressure

- Measurement errors from residual gases

The sample pump1 is, quite literally, the lungs of the gas analyzer2.

What Technical Parameters Determine the Right Pump Choice?

When choosing a sample pump, you should evaluate the following five parameters:

| Parameter | Why It Matters | Ideal Range |

|---|---|---|

| Flow Rate (L/min) | Matches the analyzer’s intake requirement | 0.2–10 L/min (portable); up to 30 L/min (fixed) |

| Vacuum/Pressure | Overcomes tubing resistance and ensures fast sampling | -60 to -98 kPa vacuum; up to 400 mbar pressure |

| Noise Level (dB) | Important for portable or medical analyzers | < 55 dB |

| Power Supply (V/W) | Must match host system; low consumption extends battery life | 12V or 24V DC; 2–10W preferred |

| Chemical Resistance | Ensures compatibility with gases like VOCs, SO₂, or NOx | PTFE, EPDM, FKM wetted materials |

Pro Tip: Always test performance under load—not just free-flow specs.

Which Pump Type Is Best for Your Gas Analysis Application?

There are three main types of pumps used in gas analyzers: diaphragm, piston, and rotary vane.

| Pump Type | Benefits | Limitations | Applications |

|---|---|---|---|

| Diaphragm | Oil-free, compact, low pulsation | Lower max pressure | VOC detectors, air quality monitors |

| Piston | Strong pressure, long tubing support | More vibration, noise | Fixed or industrial analyzers |

| Rotary Vane | Smooth flow, high vacuum (lab-grade) | Often oil-lubricated; larger footprint | Laboratory GC/MS, rack analyzers |

Diaphragm pumps are typically preferred in modern OEM designs due to:

- Their compact size and low weight

- Long service life (up to 10,000+ hours)

- Clean, oil-free operation

How Do Sample Pumps Fit Into Different Gas Analyzer Categories?

1. What Pump Is Best for Portable Gas Analyzers3?

- Application: Personal gas detectors, confined space monitoring4

- Priorities: Compact size, quiet operation, low power draw

- Example Model: BD-05T02500B

- 5V, 500mL/min, -45 kPa vacuum

- Size < 17mm, weight 22g

- Brushless motor with PWM speed control

2. What Pump Works Well in Fixed Gas Monitoring Systems?

- Application: VOC monitoring5, emission detection

- Priorities: Stable high flow, long-life motor, corrosion resistance6

- Example Model: BD-05T1040DU (Dual-head)

- 12V or 24V, up to 40 L/min, -98 kPa vacuum

- Aluminum housing, EPDM rubber

- Dual-head for high vacuum with low ripple

3. What Pump Is Suitable for Lab-Grade Gas Sampling?

- Application: GC/MS, sorbent tube sampling, analyzers with filters

- Priorities: Ultra-low noise, precision flow control, speed adjustability

- Example Model: BD-05TVB

- Flow: 4.6 L/min, vacuum: >-70 kPa

- Supports analog or PWM signal control

- Compact and ultra-quiet < 55 dB

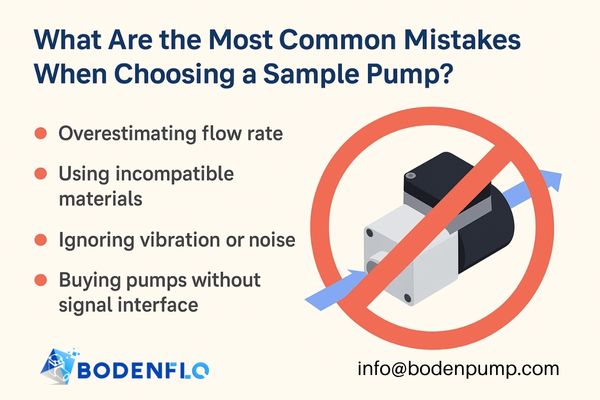

What Are the Most Common Mistakes When Choosing a Sample Pump?

Selecting a sample pump may seem straightforward, but many engineers and procurement teams fall into common traps—leading to poor sensor performance, early pump failure, or costly redesigns. Below are five frequent mistakes that should be carefully avoided during your selection process:

-

Overestimating the Flow Based on Free-Flow Ratings

Free-flow specs do not reflect real performance under vacuum or load. -

Using Incompatible Materials with Target Gases

Gases like NH₃, Cl₂, and O₃ degrade common rubber. Use PTFE, FKM, or EPDM. -

Ignoring Noise, Vibration, and Mounting Requirements

Especially important for portable or medical devices. -

Choosing Pumps Without Control Interface Compatibility

Look for PWM, analog input, or FG signal support. -

Neglecting Duty Cycle and Expected Lifespan

Always confirm the pump is rated for 24/7 use with ≥5,000h lifespan.

How Can Custom Micro Pumps Improve Your Gas Analysis Product?

Standard pumps often require adaptation. That’s why BODENFLO supports OEM customization7, including:

- Flow/pressure tuning

- Housing and port redesign

- Signal wire configuration: 2-pin, 3-pin, PWM, FG

- Material upgrades for chemical resistance

Case Study:

A client from Brazil requested a dustproof, quiet diaphragm pump8 for their agriculture-focused gas analyzer. We developed a sealed brushless BD-05T067L variant, with <50 dB noise, IP-rated connectors, and PTFE internal lining9. Their analyzers are now operating across South America in greenhouse air monitoring.

What Should You Ask Before Finalizing Your Sample Pump?

Use this checklist before finalizing your decision:

| Question | BODENFLO Recommendation |

|---|---|

| Is the pump oil-free and maintenance-free? | ✅ Diaphragm and dry piston models only |

| Does it meet your analyzer's flow needs under load? | ✅ Confirm performance curve under vacuum |

| Is the pump motor brushless for long life? | ✅ Choose brushless DC for >5,000h lifespan |

| Is it suitable for continuous or PWM speed control? | ✅ Request 3-wire or 4-wire signal types |

| Are materials chemically compatible? | ✅ Use FKM, EPDM, or PTFE based on gas type |

Why Choose BODENFLO Micro Pumps for Your Gas Analyzer?

At BODENFLO, we specialize in high-performance oil-free diaphragm and piston pumps optimized for:

- Gas detection

- Gas sampling

- Environmental monitoring

- VOC and toxic gas analysis

Our advantages:

- ✅ Vacuum range:-30~-100 kPa

- ✅ Flow range: 0.3~60 L/min

- ✅ 12V/24V brushless motor or brush motor

- ✅ OEM customization for signal, shape, or materials

📩 Contact us: info@bodenpump.com for datasheets, samples, or custom development.

-

Learn about the critical role of sample pumps in gas analysis and how they ensure accurate measurements. ↩

-

Explore this link to understand the various types of gas analyzers and how they are used in different industries. ↩

-

Explore this link to discover top-rated portable gas analyzers that meet your monitoring needs effectively. ↩

-

Learn about confined space monitoring to understand its significance in ensuring safety in hazardous environments. ↩

-

Explore this link to find expert recommendations on pumps specifically designed for VOC monitoring, ensuring accurate and reliable results. ↩

-

Understanding the significance of corrosion resistance can help you choose durable pumps that withstand harsh environments, enhancing system longevity. ↩

-

Explore how OEM customization can enhance product performance and meet specific needs in gas analysis. ↩

-

Learn about essential features like dustproofing and noise reduction that improve gas analysis efficiency. ↩

-

Discover the advantages of PTFE lining in pumps, especially for chemical resistance in various applications. ↩