Your device is perfect, but the pump noise is driving users crazy. This constant buzzing and vibration can ruin the user experience and make your product seem cheap.

Low-noise micro pumps achieve quiet operation by addressing three key areas: minimizing internal vibration, precisely balancing the motor to reduce eccentric motion, and designing the housing to dampen sound and prevent resonance, rather than amplifying it.

As a project manager at BODENFLO, I've overseen many projects where silent operation was non-negotiable. I've seen firsthand how a noisy pump can ruin a brilliant product, so my job is to work with our engineers to find and eliminate every source of sound. The quest for a truly quiet pump is a journey into the physics of sound and vibration. It’s not about one single fix; it’s about a dozen small, deliberate engineering choices that add up to a silent performance. Let's pull back the curtain and see what it really takes to engineer silence into a miniature diaphragm pump.

Where Does All That Noise in a Micro Pump Actually Come From?

You hear a constant buzz from your device. You've isolated the pump, but can't pinpoint the exact source of the sound. That annoying noise is a complex mix of mechanical and airborne vibrations.

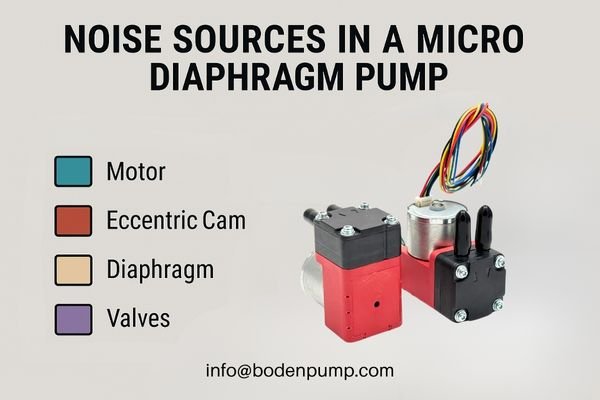

The primary noise sources in a micro diaphragm pump are the motor's rotation, the eccentric cam mechanism's vibration, the diaphragm's pulsation, and the impact of the valves opening and closing. Each component generates its own frequency, which combine to create the overall noise profile.

Breaking Down the Symphony of Sound

When our engineers analyze a pump in the acoustics lab1, they don't just hear "noise"; they see a spectrum of different frequencies. Every moving part tells a part of the story. The DC motor contributes a high-frequency hum, the eccentric mechanism creates a lower-frequency vibration from its unbalanced rotation, and the diaphragm itself produces pressure pulses in the air that we perceive as sound. The first step in any of our quiet-pump projects is to identify the loudest offender. Is it the motor, the mechanics, or the airflow itself?

| Noise Source | Type of Noise | Frequency | Common Cause |

|---|---|---|---|

| Motor | Electrical Hum | High | Commutator brushes, bearing imperfections |

| Eccentric Cam | Mechanical Vibration | Low to Medium | Unbalanced mass, bearing play |

| Diaphragm | Air Pulsation | Low | Air displacement, turbulent flow |

| Valves | Impact Noise | High, sharp clicks | Valve plate hitting the seat |

By tackling each source individually, we can systematically reduce the overall decibel level.

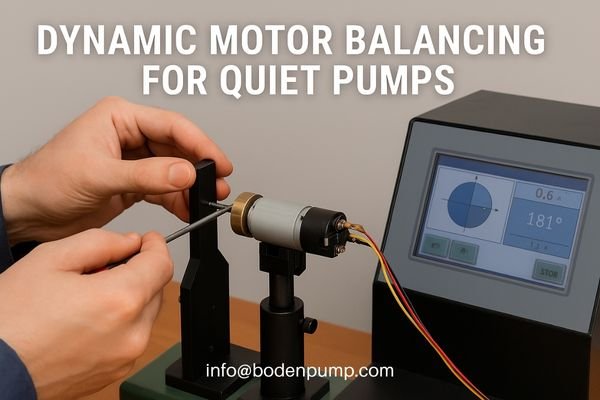

How Can Motor Balancing Make a Pump Almost Silent?

You've tried mufflers and foam, but the core vibration persists. The problem might not be what you add on the outside, but what’s unbalanced on the inside. The motor is often the heart of the noise problem.

Motor balancing is the process of adding or removing tiny amounts of mass from the motor's rotor to ensure its center of mass is perfectly aligned with its center of rotation. This eliminates the "wobble" that generates powerful, low-frequency vibrations and noise.

The Art of Perfect Equilibrium

I remember working on a project for a medical device where the client needed near-silent operation. No matter what we did to the housing, a deep hum remained. The culprit was a tiny imbalance in the motor's eccentric weight. Our engineering team put the motor on a dynamic balancing machine2, which spins the rotor and uses sensors to detect microscopic wobbles.

The machine then tells them exactly where to drill a tiny hole or add a dab of epoxy to counteract the imbalance. It's a process that requires incredible precision. A properly balanced motor doesn't just run quieter; it also runs smoother, which extends the life of the bearings and the entire dc diaphragm pump. It’s one of the most effective, yet invisible, features of a premium low-noise micro pump3.

Why Does the Pump's Casing Sometimes Make the Noise Worse?

You’ve chosen a quiet pump, but after installing it in your device, it’s louder than before. You’ve just discovered housing resonance. The casing isn't just a box; it's an instrument.

Housing resonance occurs when the pump's vibration frequency matches the natural vibrating frequency of its enclosure. This amplifies the sound, turning the casing into a speaker. A low-noise design requires a housing made from materials and shapes that avoid these resonant frequencies.

Designing a "Dead" Enclosure

Think of a guitar. Its hollow wooden body is designed to resonate and amplify the sound of the vibrating strings. Many plastic enclosures do the exact same thing with a pump's vibrations, but unintentionally. One of the biggest challenges I see in OEM projects is ensuring the customer's device doesn't turn into an amplifier for our pump.

We use Finite Element Analysis (FEA)4 software to simulate how a housing will react to the pump's specific vibration profile. The goal is to create a "dead" enclosure that absorbs energy instead of radiating it. This often involves adding ribs to change stiffness, using mixed materials with different damping properties, or ensuring there are no large, flat surfaces that can act like a drumhead. It's a critical step that separates a genuinely quiet system from one that only looks good on paper.

What Are the "Secret" Materials Used to Dampen Sound?

You've tried standard plastic and metal housings, but they still transmit too much noise. The materials you choose are just as important as the design. Some materials are naturally better at absorbing sound.

Sound-dampening materials like Santoprene™ TPV, silicone, and thick-walled ABS are used in low-noise pumps. These materials have high internal friction, which converts sound wave energy into a tiny amount of heat, effectively "killing" the vibration before it can become audible noise.

The Science of Material Damping

Choosing the right material is a balancing act between structural integrity, chemical resistance, and acoustic properties. For our quietest miniature diaphragm pump models, we often recommend a multi-material approach5.

- The Pump Body: The engineers might use a glass-filled polymer for rigidity but over-mold it with a soft thermoplastic vulcanizate (TPV). The rigid core provides the structure, while the soft outer layer acts like a built-in shock absorber.

- The Mounts: Instead of mounting the pump directly to the chassis, we advise clients to use silicone grommets6. Silicone is excellent at isolating low-frequency vibrations, preventing the motor's hum from transferring into the device's main structure.

- Internal Components: Even the choice of diaphragm material can affect noise. A more flexible elastomer might produce a smoother, less abrupt pressure pulse, softening the sound of the diaphragm air pump in operation.

Through managing many such projects, I've learned that you can't just pick a material from a catalog; you have to test it to see how it truly performs.

How Do We Test for Noise and Vibration at BODENFLO?

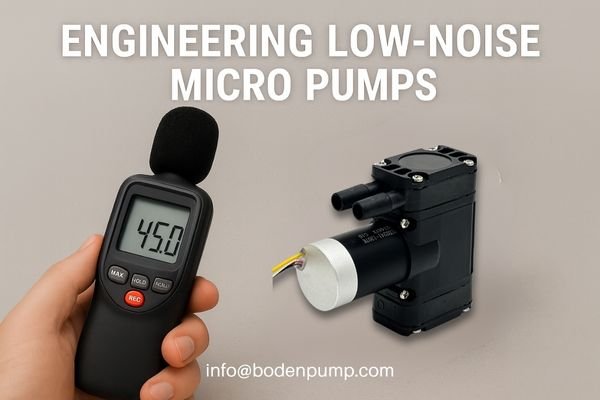

You can’t improve what you can’t measure. Simply listening to a pump isn't enough to engineer a quiet product. You need objective data to identify problems and verify solutions.

At BODENFLO, we use a semi-anechoic chamber to isolate the pump from external noise. A precision microphone measures the sound pressure level (dBA), while accelerometers attached to the pump measure the intensity and frequency of vibrations, giving us a complete acoustic profile.

The Quest for Objective Data

Walking into our acoustics lab is like entering another world. The walls are covered in foam wedges that absorb all sound reflections. In this controlled environment, we can get pure, objective data on a pump's performance. The microphone gives us the overall loudness, but the accelerometers are where the real detective work happens.

They provide a vibration spectrum7—a graph showing the exact frequencies the pump is producing. This data allows us to compare the "before" and "after" spectrums of a design change to see exactly how effective it was. This data-driven approach removes the guesswork from my projects and allows us to make targeted improvements to create a truly low-noise micro diaphragm pump.

When Is a Low-Noise Micro Pump the Right Choice for Your Design?

A powerful pump is great, but a noisy one can be a deal-breaker. In many modern applications, user experience is paramount, and audible noise is a significant part of that experience.

A low-noise micro pump is essential for medical devices used near patients, laboratory instruments in quiet environments, and premium home-use products where perceived quality is critical. In these applications, silent operation is not a luxury—it is a core design requirement.

Where Silence is Golden

Over the years, the demand for quiet pumps8 has exploded. It's no longer just a niche request. I've had the privilege of managing projects that integrated our quietest pumps into a wide range of products where noise directly impacts function and value.

- Point-of-Care Medical Devices: Imagine a wearable therapeutic device. If it's constantly buzzing, the patient will be uncomfortable and may not adhere to their treatment. Here, silence equals comfort and compliance.

- Analytical Instruments: In a lab, multiple instruments may be running at once. If each one adds to the ambient noise, it creates a stressful and distracting work environment.

- Luxury Consumer Goods: For things like high-end coffee machines or skincare devices, a loud pump cheapens the experience. The quiet, smooth operation reinforces the feeling of premium quality.

If your product operates close to the user, the investment in a low-noise micro pump9 will always pay for itself in customer satisfaction.

Conclusion

Engineering a low-noise micro pump is a holistic process of managing vibration and resonance. It requires balancing the motor, dampening vibrations with smart materials, and designing a non-resonant housing.

BODENFLO specializes in designing and manufacturing custom low-noise micro diaphragm pumps for noise-sensitive applications. Contact us at info@bodenpump.com to discuss your project.

-

Explore this link to understand the role of acoustics labs in analyzing sound and noise, enhancing your knowledge of sound engineering. ↩

-

Understanding dynamic balancing machines can enhance your knowledge of precision engineering and its impact on device performance. ↩

-

Exploring the advantages of low-noise micro pumps can help you appreciate their applications in sensitive environments. ↩

-

Understanding FEA is crucial for optimizing designs and ensuring effective vibration control in engineering projects. ↩

-

Explore this link to understand how a multi-material approach can enhance product performance and durability. ↩

-

Discover the benefits of silicone grommets in isolating vibrations and improving device performance. ↩

-

Learn about vibration spectrums to see how they help in analyzing equipment performance and improving designs. ↩

-

Explore how quiet pumps enhance patient comfort and compliance in medical devices, making treatments more effective. ↩

-

Discover the impact of low-noise micro pumps on user experience and product quality, crucial for luxury goods. ↩