Inaccurate particle counts can lead to failed cleanroom certifications or flawed environmental data. If your instrument's readings are inconsistent, the problem might be the tiny, unseen engine inside: the vacuum pump.

The best choice for air sampling is a micro rotary vane pump with a stable 6 L/min flow, such as the BD-05T01HR6L or A6-05CL. Its smooth airflow, oil-free operation, and long-life motor ensure the accuracy and reliability essential for precise analysis.

Throughout my career as a project manager, I've had in-depth discussions with the engineers who design and build high-sensitivity instruments like particle counters. A recurring theme is the challenge of ensuring measurement repeatability. After they've perfected the laser optics and the software algorithms, the final piece of the puzzle is always the fluidics. They need a pump that can pull a perfectly steady, known volume of air through the sensor. This is where the choice of pump technology becomes absolutely critical, and why a specific type of micro pump is the industry standard.

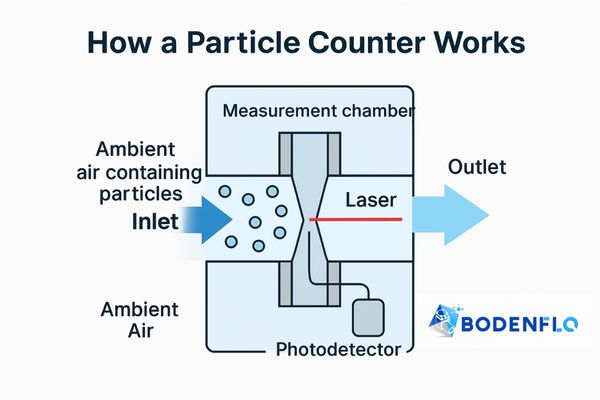

What is a Particle Counter and Why Does it Need a Vacuum Pump?

You know that particle counters are vital for monitoring cleanrooms and air quality. But the complex technology inside can seem like a black box, making it hard to troubleshoot.

A particle counter operates by pulling a precise volume of air through a laser beam. The vacuum pump is the essential component that provides the stable suction needed to ensure this sample volume is constant and accurate.

The core principle of a modern particle counter is surprisingly straightforward. It's all about light scattering1. The instrument pulls ambient air into a special measurement chamber where a focused laser beam creates a "detection zone." When a particle passes through this beam, it scatters the light. A sensitive photodetector2 picks up these flashes of light to count and size the particles.

The entire accuracy of this process hinges on one critical assumption: that the volume of air being sampled per minute is exactly what the machine thinks it is. The pump's job is to make that assumption a reality by providing a perfectly stable and consistent airflow.

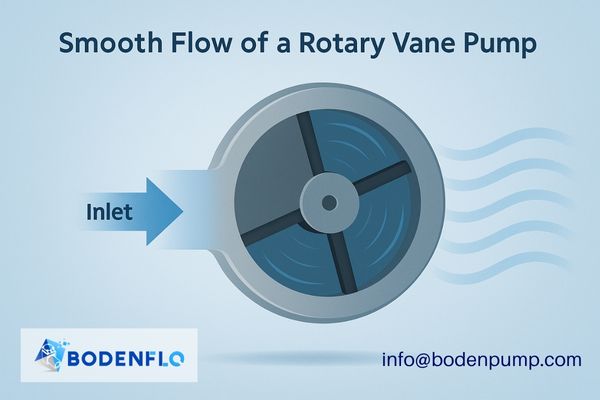

Why is a Rotary Vane Pump the Preferred Technology?

You need a pump for your instrument, but other technologies like diaphragm pumps are common. This can lead to confusion about which type is truly best for high-sensitivity air sampling.

A micro rotary vane pump is preferred because it generates an exceptionally smooth, non-pulsating airflow. This stability is critical for the laser sensor, which requires a steady sample stream for accurate and repeatable particle detection.

While diaphragm pumps are excellent for many applications, they inherently create small pressure pulses in the airflow. For a highly sensitive particle counter, these pulses can be misinterpreted as fluctuations in particle density, leading to "noise" in the data.

A rotary vane pump avoids this problem by design. It uses a rotor with sliding vanes that trap and move pockets of air from the inlet to the outlet in a smooth, continuous motion. This mechanism produces a much quieter, vibration-free, and stable airflow. This is precisely why it has become the gold standard for high-performance instruments.

What Features are Essential for a Particle Counter Pump?

You assume any small, oil-free pump will work. But using a pump not designed for instrumentation can introduce contamination, defeating the entire purpose of the particle counter.

The key features are non-negotiable: 100% oil-free operation, low particle shedding, stable flow, and a long-life motor. These ensure the pump doesn't contaminate the sample or degrade the instrument's accuracy.

When I consult with instrument designers, we focus on a specific checklist of pump features. The pump cannot be a source of error; it must be a silent, reliable partner to the optics.

Key Pump Characteristics

- Low Vibration and Flow Stability3: The pump's mechanical design must be optimized to provide a large, stable flow without vibration or pulsation.

- Long-Life Motor4: Instruments used for continuous monitoring need a reliable motor. A high-performance coreless DC motor with a lifespan of over 8,000 hours is the benchmark.

- High Gas Tightness: The pump casing must be perfectly sealed to prevent ambient air leaks or sample gas loss, ensuring sample integrity.

- Clean Operation: The pump must be oil-free, and its internal components (like vanes) must be made of high-purity graphite that doesn't introduce contaminating particles.

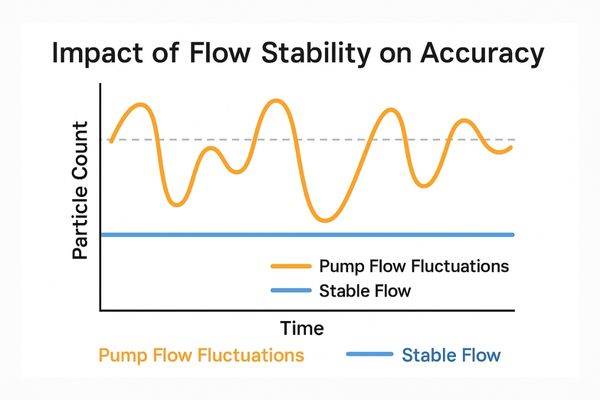

How Does Flow Stability Directly Impact Measurement Accuracy?

Your particle counter's results are fluctuating, even in a stable environment. You suspect the sensor is faulty, leading to time-consuming and expensive troubleshooting.

Vacuum stability has a direct, mathematical impact on accuracy. The final particle count is calculated based on a fixed flow rate, so any fluctuation in the pump's flow creates a direct error in the final reading.

This is a point I always emphasize with engineering teams. The software inside the particle counter doesn't actively measure the flow rate in real-time; it assumes5 the rate is constant. A common standard is 2.83 liters per minute (L/min).

The final calculation is essentially: Particles/m³ = (Particles Counted / Assumed Flow Rate) x Conversion Factor. If the pump's actual flow drops to 2.7 L/min due to instability, but the software still calculates based on 2.83 L/min, every single reading will be artificially high. This is why a stable pump6 is the foundation of any trustworthy measurement.

What are the Risks of Using a Low-Quality Pump?

Choosing a cheaper, generic pump seems like a simple way to reduce the bill of materials cost. However, this small saving can lead to huge downstream costs from warranty claims and reputational damage.

A low-quality pump introduces multiple failure points. It can generate inaccurate data, fail calibrations, and even destroy the instrument's optics, ultimately leading to product recalls and a loss of customer trust.

This is a classic example of a small component causing a big problem. The risks are significant and costly:

- Inaccurate Data: The instrument provides numbers that cannot be trusted, potentially causing a cleanroom to fail an audit.

- Self-Contamination: A cheap pump can shed its own wear particles, causing the counter to report high particle counts that aren't actually there.

- Optical Damage: An oil-based pump can release vapors that form a film on the laser and sensor optics, permanently damaging them.

- Short Lifespan: Premature pump failure leads to instrument downtime, warranty returns, and unhappy customers.

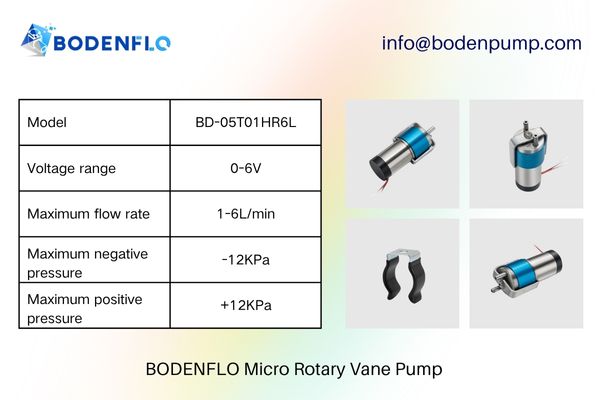

How Does the BODENFLO BD-05T01HR6L Meet These Demands?

You need a reliable, high-performance pump for your instrument, but navigating the market is complex. You need a proven solution from a partner you can trust.

We understand the challenges faced by instrument manufacturers. While common models like the A6-05CL are known, there is constant pressure to find components that offer both high performance and excellent value. As a China-based manufacturer, we leverage our advanced production capabilities to offer the BD-05T01HR6L. This pump provides world-class performance at a highly competitive price point, allowing you to reduce your bill of materials without compromising on quality.

- Engineered for Stability: Its optimized body and oil-free rotary vane principle7 provide a large flow that is exceptionally stable and free of pulsation.

- Built for Endurance: A high-performance coreless DC motor8 delivers a lifetime of over 8,000 hours, and the excellent pump head design reduces operational noise.

- Guaranteed Integrity: We ensure a high level of gas tightness to prevent any contamination of the sample gas.

- Advanced Control: For dynamic applications, it can provide positive and negative rotation to change the gas flow direction at any time.

This model is the ideal choice for particle counters, 2.83L sampling instruments, VOC online analyzers, and medical instruments

| Specification | BODENFLO Model BD-05T01HR6L |

|---|---|

| Voltage Range | 0-6V (12V Optional) |

| Max Flow Rate | 1-6 L/min |

| Max Negative Pressure | -12 kPa |

| Motor Type | Coreless DC Motor |

| Lifetime | 8000 hours |

| Pump Head / Case | 304 Stainless Steel |

| Vane Material | High-Purity Graphite |

| Weight | 118g |

Conclusion

A high-quality micro rotary vane pump is not just an accessory for a particle counter — it is a core component that guarantees the accuracy and reliability of the entire instrument.

At BODENFLO, we specialize in providing precision-engineered micro rotary vane pumps designed for cleanroom monitoring and air particle counters. Contact our team at 📧 info@bodenpump.com to discuss your application and find the ideal pump solution for your instrument today.

-

Understanding light scattering is essential for grasping how particle counters work and their accuracy. ↩

-

Exploring the role of sensitive photodetectors can enhance your knowledge of particle measurement technology. ↩

-

Understanding these benefits can help you choose the right pump for your needs, ensuring optimal performance. ↩

-

Exploring this topic will provide insights into the reliability and efficiency of pumps, crucial for continuous monitoring. ↩

-

Understanding assumptions in flow rate can help improve measurement accuracy and reliability in engineering. ↩

-

Exploring the significance of a stable pump can enhance your knowledge of measurement integrity in engineering applications. ↩

-

Understanding this principle can enhance your knowledge of stable and efficient gas flow systems. ↩

-

Exploring this topic will reveal how coreless DC motors improve performance and longevity in various devices. ↩