When diving into the world of Original Equipment Manufacturer (OEM) micro pumps, one question stands out: how customizable are they? The ability to tailor these pumps to specific applications can make or break your operation's efficiency. So let's get into the nuts and bolts of micro pump customization.

OEM micro pumps offer a high degree of customization, ranging from flow rates and pressure levels to material selection, all tailored to suit specific industry requirements.

So, why does customization in OEM micro pumps matter? In the next sections, this guide will delve into the various types of micro pumps, key considerations in material selection, and essential quality control standards. Whether you're a procurement officer or an engineer, the insights ahead will arm you with the knowledge to make informed decisions. Let's get started.

Why Customization Matters

In today's hyper-competitive marketplace, the 'one-size-fits-all' approach no longer cuts it, especially in sectors requiring specialized equipment like micro pumps. Customization isn't merely an added benefit; it's a business imperative. Here are some compelling reasons why customized pumps are non-negotiable in today's environment.

Efficiency

When you can tailor a pump's design and features to your specific operational needs, the gains in efficiency are substantial. By customizing parameters such as flow rate, pressure, and energy usage, you can ensure that your pump is operating at peak efficiency. This not only leads to better performance but also reduces the energy footprint, contributing to a more sustainable operation.

Cost-Effectiveness

It might seem counterintuitive, but customized pumps can actually save you money in the long run. Although the upfront costs may be higher, tailored solutions can lower your total cost of ownership. How? By reducing maintenance costs, minimizing the need for spare parts, and decreasing the downtime associated with malfunctions or inefficiencies.

Meeting Quality Standards

In industries like healthcare, automotive, and manufacturing, adhering to stringent quality standards and certifications is not optional. Custom pumps can be designed to meet or exceed these industry-specific guidelines. Whether you require FDA compliance, ISO certification, or any other specialized accreditation, a custom-built micro pump can be designed to meet those exact requirements, thereby ensuring you're always in compliance.

Customization is not just about getting what you want; it's about getting what your operation needs to be efficient, compliant, and competitive. By investing in customized micro pumps, you're investing in a tailored solution that brings long-term value to your operations.

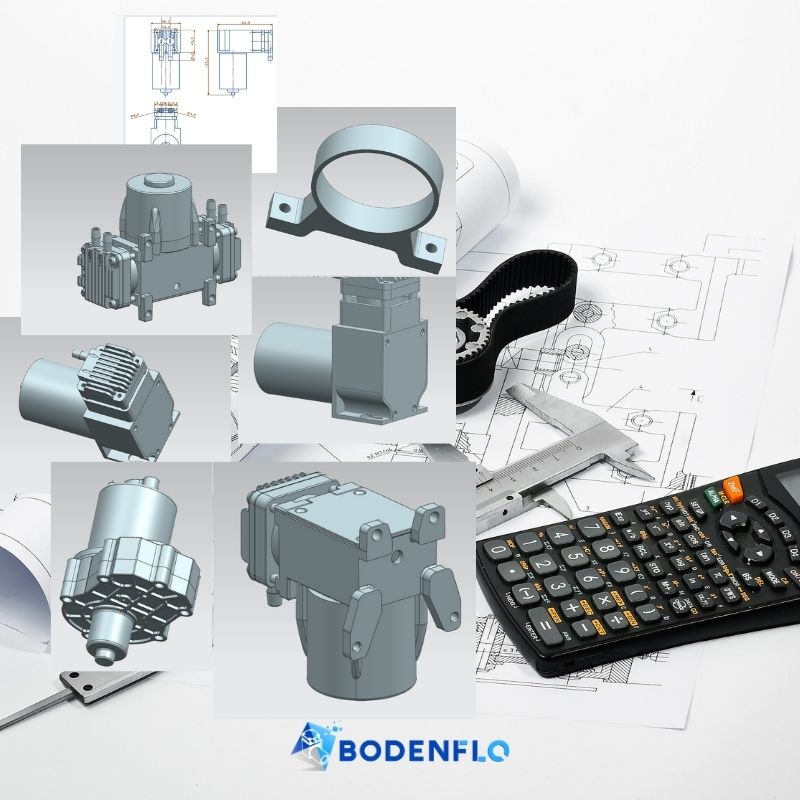

Levels of Customization

Customization in the micro pump industry isn't a monolithic concept; it exists on a spectrum. Depending on your unique requirements and constraints, you can opt for different levels of customization, each with its own benefits and considerations. Let's delve into these layers to gain a better understanding.

Basic Customization

At the most fundamental level, basic customization involves aesthetic or superficial changes. These can include alterations in color, applying your company branding, or even basic tweaks in performance parameters like speed settings. While these adjustments may seem minor, they're often the quickest to implement and can still offer a level of differentiation in the marketplace.

Moderate Customization

When you need more than just a coat of paint, moderate customization comes into play. This level involves significant adjustments in the technical specifications of the pump. You could opt for changes in flow rates, pressure levels, or even the type of power supply the pump uses. These modifications can improve the pump's compatibility with your specific applications, without the need for a complete overhaul of the design.

Advanced Customization

At the highest tier, advanced customization provides a near-complete overhaul of the pump's core design and function. This can involve tailoring pumps to operate under extreme environmental conditions, such as high temperatures or corrosive materials. It can also include incorporating cutting-edge materials like PTFE elastomers for enhanced chemical resistance. These changes are substantial, and they often require a longer lead time and greater investment. However, the payoff is a product that's precisely engineered for your specialized needs, offering unparalleled performance and reliability.

Understanding the level of customization that best suits your needs can significantly streamline your procurement process and improve overall performance. With each tier of customization, the investment of time and resources increases, but so does the value that these custom solutions can deliver.

Factors Influencing Customization

Navigating the realm of pump customization isn't merely about deciding what you want; it's also about understanding what you need. Several critical factors come into play when determining the extent of customization suitable for your project. Here's a closer look at some of these influential parameters.

Material Choice

Material compatibility is paramount, particularly when it comes to micro liquid pumps. Whether you're pumping corrosive chemicals or high-temperature fluids, the material of the pump should be up to the task. For example, PTFE elastomers excel in chemical resistance, while stainless steel may be the go-to for high-temperature operations.

Operational Conditions

Your operating environment plays a significant role in influencing customization. Parameters like operational pressure, temperature ranges, and even the pump's duty cycle can drastically affect performance. It's essential to provide manufacturers with accurate data on these conditions to achieve a truly optimized pump.

Industry Regulations

Compliance is not just a box to tick; it's often a stringent requirement in industries such as healthcare, food and beverage, or petrochemicals. Depending on your industry, you might need pumps that meet FDA standards, ATEX certifications, or other regulatory criteria. Customization here ensures that you're not just getting a pump that works but one that works within the legal framework of your industry.

The level of customization you might require is often a complex interplay of multiple factors. Understanding these can help you communicate more effectively with manufacturers, ensuring that the end product aligns closely with your operational needs and compliance requirements.

Industry-Specific Customizations

The customization journey doesn't follow a one-size-fits-all approach. Different industries come with unique sets of challenges and compliance standards that can significantly influence the customization of micro pumps. Let's delve into some industry-specific customization nuances.

Medical Industry

In the medical field, precision isn't a luxury; it's a necessity. Micro pumps in medical applications often require high accuracy for dosing and fluid transfer. On top of that, the materials used must be biocompatible to ensure patient safety. Whether it's for drug delivery systems or diagnostic equipment, custom micro pumps designed for medical use need to meet stringent quality and safety standards.

Manufacturing Industry

Manufacturing settings often require robust and efficient pumps that can withstand the rigors of constant use. Durability is a key factor, as any downtime can result in substantial financial losses. Here, customization may focus on materials like stainless steel for longevity and mechanisms designed for low maintenance and high throughput.

Food & Beverage Industry

When it comes to food and beverage applications, compliance with food safety standards is non-negotiable. Custom pumps in this sector often need to be made of food-grade materials and should be easy to clean or sterilize. This ensures that the pumps not only meet performance expectations but also adhere to safety and hygiene regulations.

Each industry's specific requirements dictate the extent and nature of customization. Whether it's precision and biocompatibility in the medical sector, durability in manufacturing, or compliance with food safety norms in food & beverage, custom miniature pumps must be tailored to meet these diverse needs effectively. This requires a collaborative approach between the client and the manufacturer to achieve an optimal customized solution.

Quality Control in Customization

Quality control is a critical aspect of customization that cannot be overlooked, as it directly impacts product performance and user safety. Here, we'll explore the crucial phases where quality control integrates with the customization process of micro pumps.

Prototyping

Prior to entering the mass production stage, a prototype is often developed. This prototype serves as a tangible representation of the customized pump and allows for rigorous quality testing under real-world conditions. It provides a platform for both the manufacturer and the customer to identify any potential issues or areas for improvement. This iterative process ensures that the final product will meet all performance and quality standards.

Quality Audits

Once production is underway, quality audits become an indispensable part of the process. Regular checks and inspections are carried out to make sure that the customizations are implemented correctly and meet the agreed-upon specifications. Advanced testing methods, from dimensional checks to functional tests, are deployed to assess various attributes like flow rate, pressure, and chemical compatibility.

Certifications

In specific industries, possessing the right certifications is not optional—it's a requirement. Depending on the sector and country of operation, various certifications like ISO 9001, FDA approval, or CE marking may be necessary. These certifications act as a testament to the product's quality, safety, and adherence to industry standards.

The objective of quality control in customization is to ensure that the final product meets or exceeds all technical specifications and industry requirements. This is accomplished through a rigorous process involving prototyping, regular quality audits, and necessary certifications. Hence, it's vital for businesses to work closely with manufacturers who have robust quality control mechanisms in place.

Conclusion

Customization in OEM micro pumps is more than just a value-added service; it's a strategic advantage that can bring about transformative changes in your operations. Whether you are part of the medical, manufacturing, or any other industry relying on precision fluid control, a custom solution allows for an efficient, cost-effective, and compliant operation.

By understanding the distinct requirements of your application and working in close collaboration with your manufacturer, you can develop pumps that are optimized for specific parameters such as flow rate, pressure, and chemical compatibility. These customizations can lead to significant efficiency gains, from reducing energy consumption to minimizing operational downtimes.

More importantly, a well-tailored pump can stand the test of time, offering long-term cost benefits and operational reliability. It also ensures that the pumps meet industry-specific regulations and certifications, thereby minimizing compliance risks.

In summary, customization is not an optional luxury but a vital requirement for staying competitive and relevant in today's fast-paced industry landscape. Hence, it's crucial to partner with a manufacturer that not only understands your needs but also has the technical prowess and quality control measures to make your customization visions a reality.

For more information on customizing your micro pumps, feel free to contact us. As the leader in micro pump technology, BODENFLO can guide you through every step of the customization process.