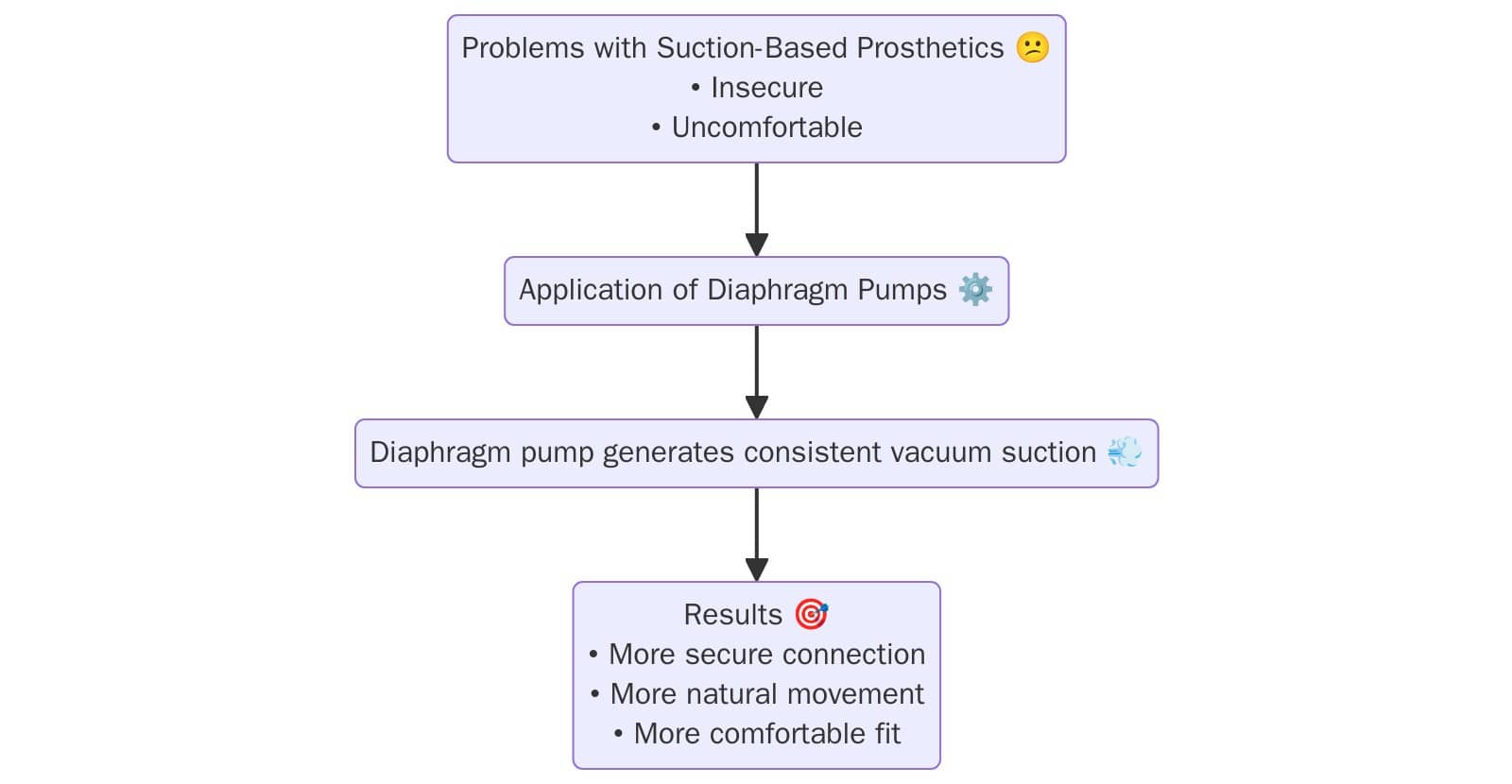

It's frustrating when technology doesn't live up to its promises, right? Especially when it impacts something as personal as a prosthetic.

Diaphragm pumps boost the functionality and reliability of suction-based prosthetics by creating a consistent vacuum, ensuring the prosthetic stays securely attached to the limb, mimicking natural movement, and providing a comfortable fit. This eliminates the need for cumbersome straps and harnesses.

I know how important it is to have reliable equipment. So, let's explore how diaphragm pumps are improving prosthetic technology, but first...

What Benefits Do Diaphragm Pumps Offer in Prosthetics?

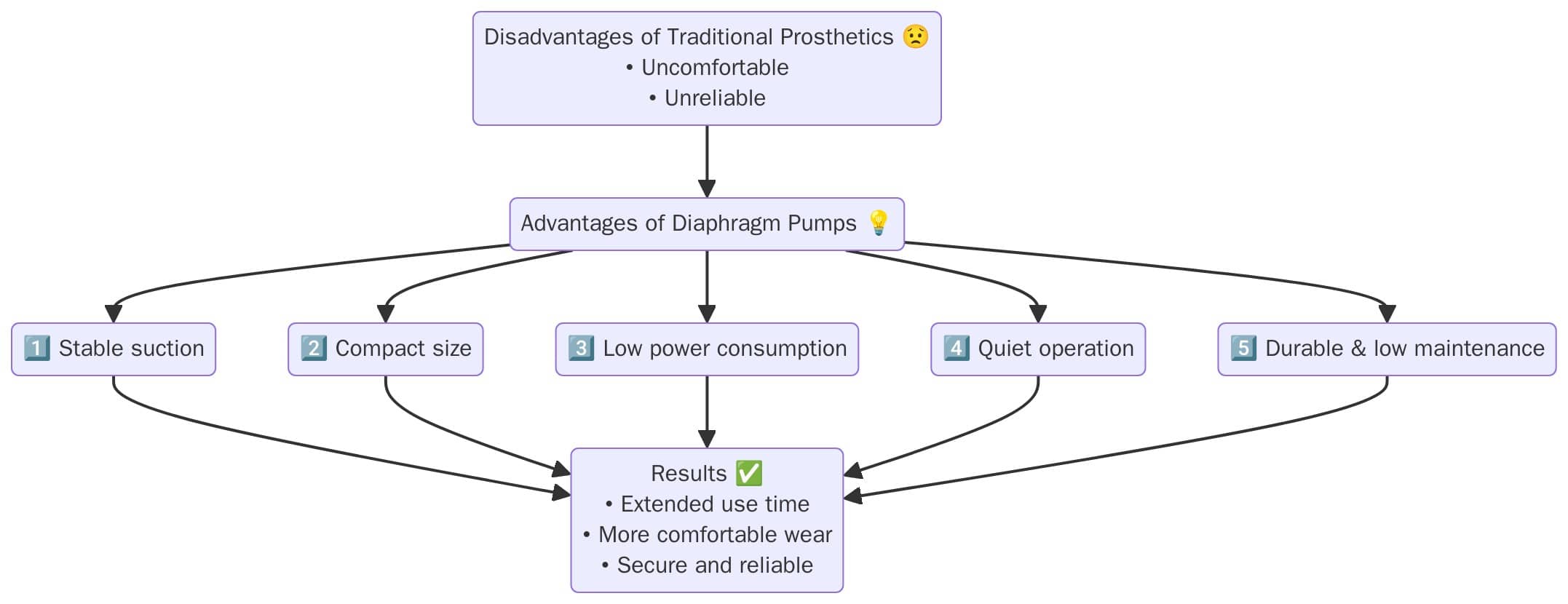

It's annoying when prosthetics are uncomfortable or unreliable, isn't it?

Diaphragm pumps offer several key benefits, including consistent suction, compact size, low power consumption, and quiet operation. They allow for extended prosthetic use without worrying about battery drain and provide a secure, comfortable fit by eliminating the need for straps.

Dive deeper:

- Consistent Suction1: Diaphragm pumps maintain a steady vacuum, which keeps the prosthetic firmly attached, even during movement. This is crucial for users who need to rely on their prosthetics for various activities.

- Compact Size: These pumps are small and lightweight, making them easy to integrate into prosthetic designs without adding extra bulk or weight. This is essential for comfort and natural movement. The 2000 Series micro diaphragm pump is one of the highest-performing pumps of its size and type.

- Low Power Consumption2: Diaphragm pumps are energy-efficient, allowing amputees to confidently use their prosthetics for longer periods without worrying about battery drainage. Some draw under 1 Watt at full vacuum.

- Quiet Operation: Low noise levels are important for discretion and comfort. Diaphragm pumps operate quietly, minimizing any unwanted attention or disturbance. The noise level at full speed can be less than 50dB.

- Durability and Low Maintenance3: Diaphragm pumps are designed for long-lasting durability and therefore have a low maintenance requirement.

What's the Big Advantage of a Piston Diaphragm Pump Over a Regular Piston Pump?

Ever wondered why some prosthetics seem more advanced than others?

Piston diaphragm pumps offer a significant advantage over standard piston pumps due to their ability to handle a wider range of fluids, including corrosive and abrasive ones, without damage. They also provide better sealing, preventing leaks and contamination, while requiring less maintenance.

Dive deeper:

Here is a table highlighting the key differences:

| Feature | Piston Pump | Piston Diaphragm Pump |

|---|---|---|

| Fluid Compatibility | Limited to clean fluids; sensitive to particulate matter and abrasive materials | Versatile; handles corrosive, abrasive fluids, and slurries |

| Maintenance | More frequent; potential wear on seals and pistons | Less frequent; fewer moving parts, reducing maintenance needs |

| Sealing | Higher risk of leaks | Excellent sealing; minimizes risk of leakage |

| Efficiency | Generally more efficient, especially at high pressures | Generally less efficient than piston pumps, especially at high pressures |

| Applications | High-pressure applications requiring clean fluids and precise control | Applications requiring versatility, resistance to abrasive or corrosive materials, and low maintenance; ideal for prosthetics |

I've seen firsthand how regular piston pumps can struggle with the demands of prosthetic use. The materials they can handle are limited, and the wear and tear can be a real issue. Piston diaphragm pumps, on the other hand, are built to last and can handle more challenging conditions.

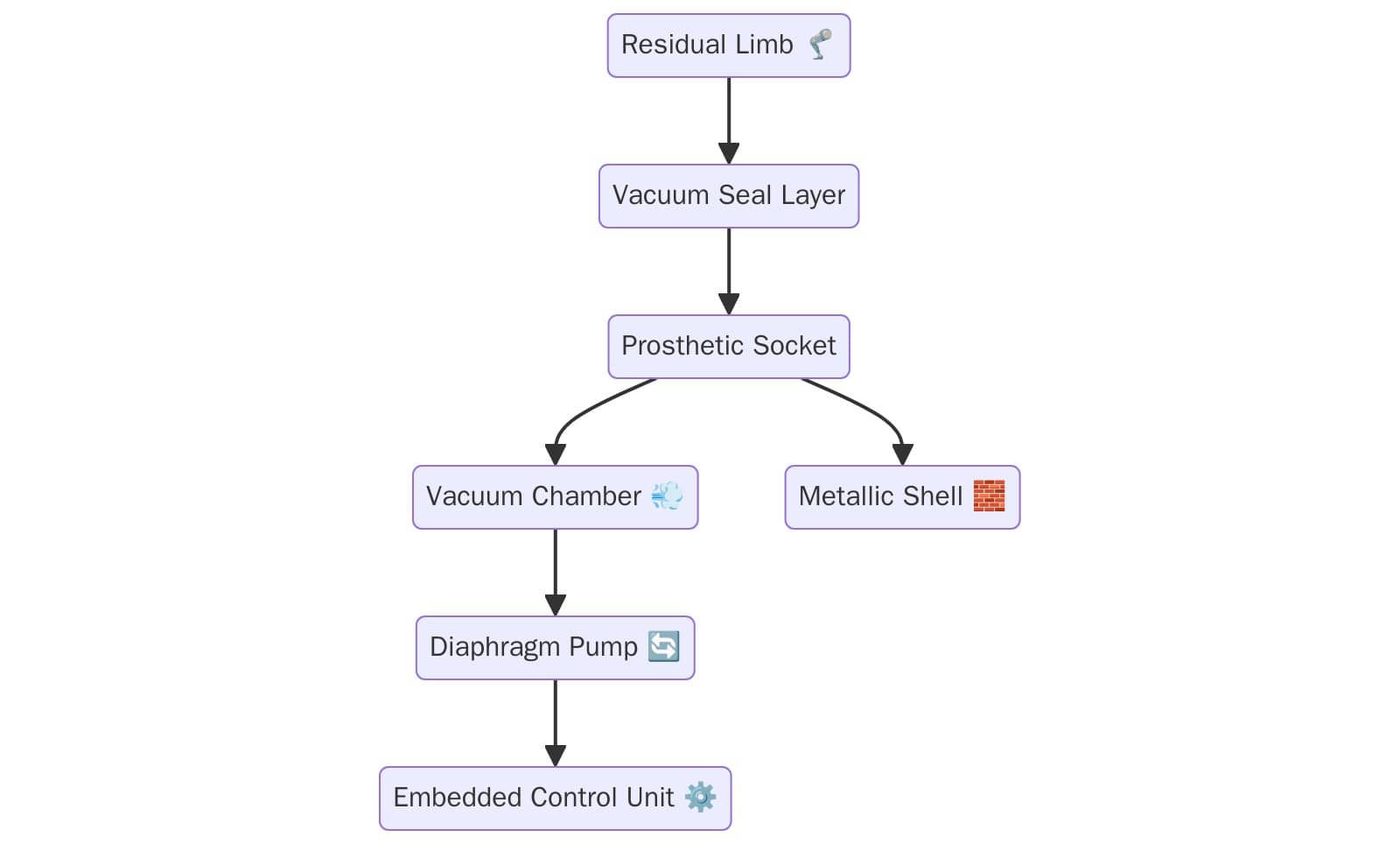

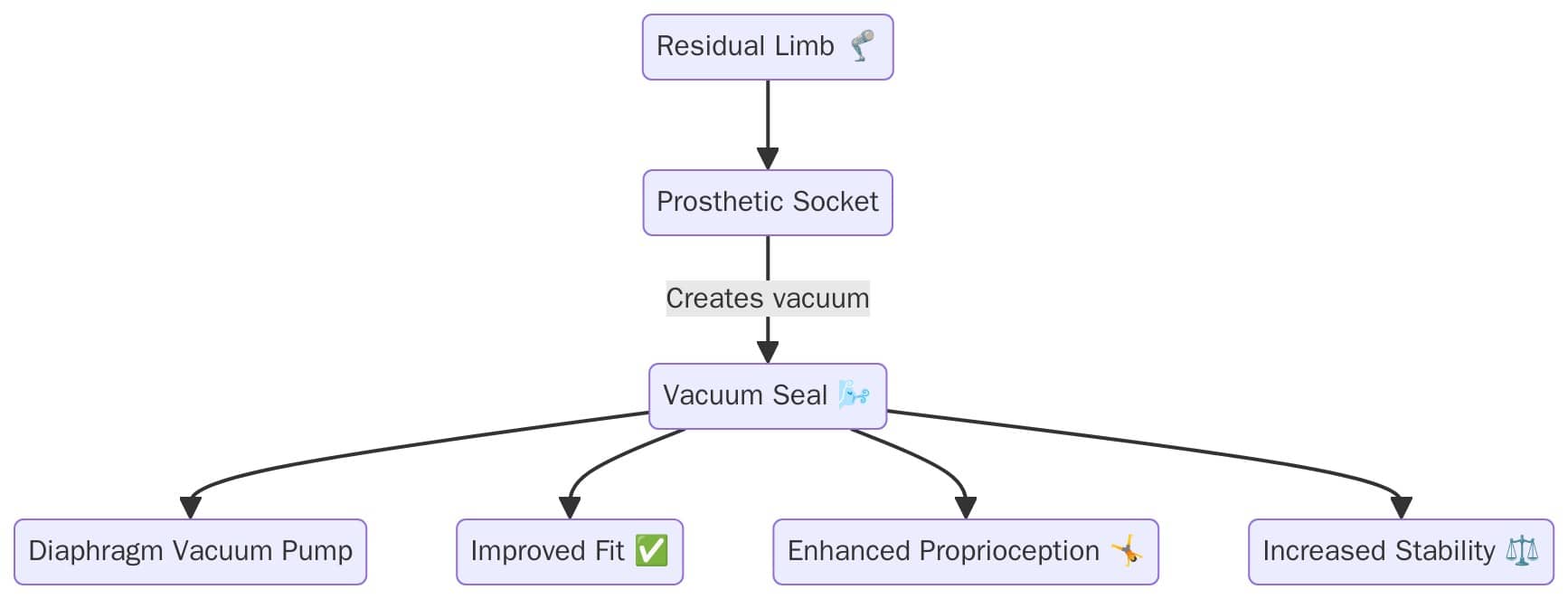

What Does a Diaphragm Vacuum Pump Actually Do?

It's hard to grasp the purpose of a device if you don't know its function, isn't it?

A diaphragm vacuum pump creates a vacuum seal between the prosthetic socket and the residual limb. This vacuum ensures a secure and comfortable fit, enhances proprioception (the sense of body position), and improves the user's overall control and stability.

Dive deeper:

- Creating a Vacuum: The pump removes air from the socket, which results in a secure attachment. The 2000 Series is able to reach ~914 mbar (27 inHg) in a few seconds.

- Maintaining Consistent Pressure: Active vacuum systems use the pump to maintain a constant vacuum level, compensating for any leaks or changes in fit throughout the day.

- Improving Comfort: By evenly distributing pressure, the vacuum helps to reduce discomfort and prevent skin irritation.

- Enhancing Proprioception: The secure fit allows for better communication between the limb and the prosthetic, improving the user's sense of body position and movement.

- Increasing Stability and Control: A well-fitted prosthetic enhances stability and allows for more precise and controlled movements.

What Kind of Suction Pressure Can a Diaphragm Pump Achieve?

Is it strong enough? Is it too strong? I often get asked these questions.

Diaphragm pumps used in prosthetics typically achieve suction pressures up to -27 inHg (inches of mercury), or approximately -914 mbar. This level of vacuum is strong enough to provide a secure grip without causing discomfort, ensuring the prosthetic remains firmly attached even during strenuous activities.

Dive deeper:

- Achieving Optimal Vacuum Levels: The goal is to reach a vacuum level that provides a secure fit without causing excessive pressure on the residual limb.

- Balancing Suction and Comfort: The design and control of the pump are crucial to achieving this balance.

- Maintaining Performance Under Load: The pump should be able to start back up under full vacuum to ensure the prosthetic remains securely attached, even during sudden movements or changes in pressure.

- Adjustability: Some pumps allow for adjustable suction levels to accommodate individual user preferences and needs.

- Safety Mechanisms: Safety features are incorporated to prevent over-pressurization or excessive suction, ensuring user safety and comfort.

Conclusion

Diaphragm pumps are transforming suction-based prosthetics. Their quiet operation, low power needs, and consistent performance deliver a better experience. This tech offers secure, comfortable, and reliable prosthetic solutions.

-

Understanding the importance of consistent suction can enhance your knowledge of prosthetic technology and its impact on user experience. ↩

-

Exploring low power consumption benefits can reveal how technology improves the daily lives of amputees, ensuring longer usage without battery concerns. ↩

-

Learning about durability and maintenance can help you appreciate the reliability of prosthetic devices, enhancing user confidence and satisfaction. ↩