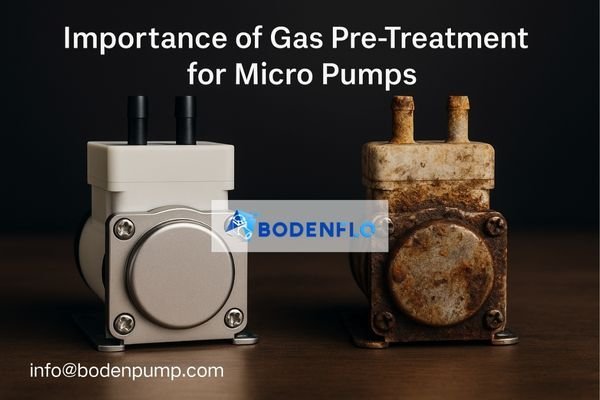

Your new gas analyzer is giving erratic readings, and worse, the micro pump inside has failed prematurely. You suspect the sample gas is the culprit, but you're unsure what kind of pre-treatment is truly necessary to protect your system.

Gas pre-treatment is non-negotiable for system accuracy and longevity. Properly filtering particles, removing moisture, and ensuring material compatibility can extend your micro pump's life by 2-3 times and guarantee stable, reliable sensor readings.

As a project manager at BODENFLO, a common issue I help engineers solve is premature pump failure. They often come to me after a pump in their gas analyzer has stopped working far earlier than expected. In almost every case, the root cause isn't the pump itself, but what's being fed into it. A micro diaphragm pump is the heart of your gas sampling system, but it's not invincible. Providing it with a clean, dry, and cool stream of gas is the single most important factor for achieving a long, reliable service life. Let's walk through what your micro pump actually needs from an engineering perspective.

Why Does Gas Pre-Treatment Matter Before the Micro Pump?

You assume a high-quality pump should handle any gas you throw at it. But now you're dealing with flow degradation and pump failures that are damaging your brand's reputation for reliability.

Gas pre-treatment acts as a crucial shield for your micro pump and downstream sensors. It prevents damage from moisture, particulates, and corrosive chemicals, directly impacting the pump's lifespan, flow stability, and the accuracy of your entire analytical system.

The Impact of Untreated Gas

Think of an unprotected micro pump like an engine running without an air or oil filter—failure is not a matter of if, but when. For instance, moist, unfiltered air can have devastating effects. Water vapor entering a warm pump cavity can condense, causing the diaphragm to fatigue and stretch, leading to a drop in flow. Fine dust can get lodged under valve flaps, causing them to leak and fail to seal, which destroys the pump's ability to pull a vacuum. Corrosive gases react with elastomers, making them brittle and prone to cracking. Pre-treatment isn't an optional extra; it is a fundamental requirement for any serious gas sampling application1.

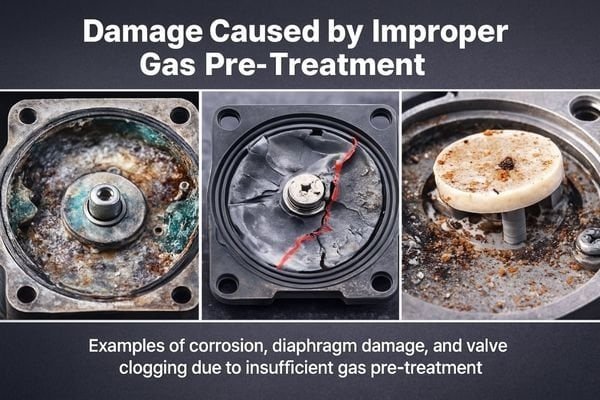

What Happens If Gas Is Not Properly Pre-Treated?

Your system is failing in the field, but the exact cause is a mystery. You see symptoms like fluctuating sensor data and noisy pumps, but you can't pinpoint the source of the problem.

Without proper pre-treatment, your system will suffer from a cascade of predictable failures. Moisture causes corrosion and blockages, particles damage critical pump components, and chemical corrosion leads to leaks and flow decay.

A Cascade of Predictable Failures

Here are the most common failure modes I see when gas isn't treated correctly.

Moisture Problems

- Vapor Ingress: Hot, humid gas enters the pump, where it can cool and condense. This leads to increased motor load, higher noise, and corrosion of internal components.

- Condensate Slugs: If liquid water is sucked into the pump, it can cause an instantaneous hydraulic lock, stalling or even burning out the motor.

Dust and Particle Damage

- Valve Failure: Fine particles get trapped under the delicate valve flaps, preventing them from sealing properly. The pump can no longer generate vacuum or pressure efficiently.

- Diaphragm Damage: Abrasive particles can score or even puncture the diaphragm, leading to a complete loss of function.

Chemical Corrosion2

- Material Degradation: Acidic gases (like SO₂, NO₂) react with standard elastomers like EPDM, causing them to harden, crack, and lose their flexibility. This leads to a gradual, irreversible decline in flow performance and eventual leaks.

Flow Instability and Sensor Error

- Sensor Drift: High humidity can cause readings to drift in sensitive sensors like PID, O₃, and NDIR, invalidating your measurement data.

- Pump Pulsation: A pump struggling with moisture or particles will often "gasp," leading to an unstable, intermittent sample flow and unreliable sensor readings.

What Type of Pre-Treatment Does a Micro Pump Actually Need?

You know you need pre-treatment, but the options are overwhelming. You're trying to balance cost with effectiveness, unsure which filters, dryers, and separators are truly necessary to protect your pump.

A micro pump requires a multi-stage pre-treatment system focused on filtration, moisture control, and material compatibility. This ensures the gas reaching the pump is clean, dry, and non-reactive, which is the key to long-term reliability.

The Core Requirements

This is the heart of the matter. Here is what your pump needs to thrive.

1. Filtration Requirements

- Pre-filter (5 μm)3: This is the first line of defense, placed at the sample probe inlet. It removes coarse dust and particles, protecting the entire sample line.

- Fine Filter (0.3 μm)4: Placed just before the pump, this filter removes fine particulates that can damage the delicate pump valves.

- Waterproof Membrane (PTFE): Often integrated with the fine filter, this acts as a final safety barrier, preventing any rogue liquid droplets from entering the pump.

2. Moisture and Dew-Point Control

- Condensers/Nafion Dryers5: These devices actively remove water vapor from the gas stream. A pump is sensitive to moisture because it can cause diaphragm fatigue and valve deformation.

- Recommended Dew Point: To be safe, the gas dew point at the pump inlet should be ≤5°C.

3. Condensate Separation

- Water Traps: If there's any chance of liquid slugs forming, a condensate separator or water trap is essential. It must be placed before the pump to prevent catastrophic liquid ingestion. A pump is designed for gas, not liquid.

4. Material Compatibility

- Acidic Gases6 (SO₂, NOx): The wetted path materials should be highly resistant, like PTFE or FKM.

- VOCs: Standard elastomers like EPDM or NBR are often suitable. The key is to match the pump's internal materials to the chemical nature of the gas after it has been pre-treated.

5. Flow Stability Devices

- Buffer Volume / Surge Chamber: A small reservoir placed after the pump can smooth out pulsations inherent in diaphragm pumps, providing a steady, laminar flow to the sensor, which is critical for precision analysis.

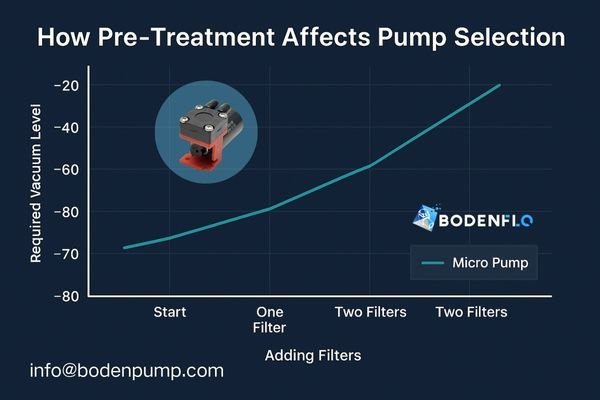

How Pre-Treatment Parameters Determine Pump Selection

You understand pre-treatment now, but how does it connect to choosing the right pump? You need to specify a pump that can handle the load of the entire sampling system, not just the gas itself.

Pre-treatment choices directly dictate pump specifications. The pressure drop across filters and dryers determines the required vacuum level, while the target application defines the necessary flow rate and material choices for the pump.

Connecting the Dots to Your Pump Spec Sheet

This is where we translate system needs into a pump order.

1. Required Flow Rate After Pre-Treatment7

Think about the net flow your sensor needs.

- 1–5 L/min: Typical for VOC monitors, PIDs, and portable analyzers.

- 3–8 L/min: Common for O₃ analysis and lab instruments.

- 10–25 L/min: Needed for high-flow CEMS and multi-point sampling systems.

2. Required Vacuum Level

The pump must overcome the resistance of all pre-treatment components.

- -20 to -80 kPa: A common range for most sampling applications.

- Higher Vacuum Needed: If your system includes long sample lines, dense filters, or a cooling condenser, you will need a pump with a stronger ultimate vacuum to maintain the target flow rate.

3. Required Pressure Stability

- <5% Flow Fluctuation: Most analytical sensors require a highly stable flow to prevent reading errors. This often necessitates a low-pulsation pump (e.g., dual-head design) or an external buffer.

4. Material Selection After Pre-Treatment

This is a key insight for cost optimization.

- Inadequate Pre-treatment: If you cannot fully remove corrosive elements, you must specify a pump with highly resistant wetted parts (e.g., full PTFE head). This is the expensive option.

- Effective Pre-treatment: If your system properly filters and dries the gas, a standard pump with EPDM elastomers is often perfectly suitable and more cost-effective. At BODENFLO, we can help you make this choice.

Recommended BODENFLO Micro Pumps for Gas Sampling Systems

You're ready to select a pump. You need specific, application-proven models that match your flow, vacuum, and size requirements.

BODENFLO offers a complete range of oil-free, maintenance-free micro diaphragm pumps. With BLDC motors rated for 8,000-10,000 hours, we have a solution for every sampling scenario, from low-flow VOC detection to high-flow CEMS.

From Small and Precise to High-Flow and Powerful

Here are some of our most popular models for gas sampling systems.

For 0.5–2 L/min Small Sampling Systems (VOC, Fixed Gas Detectors)

- BD-05T02500B: High precision and compact. Ideal for fixed detectors requiring stable, low flow. (500 ml/min, -45 kPa)

- BD-05T01.51000EP: Low noise and excellent stability. A great choice for portable devices. (1 L/min, -40 kPa)

For 3–8 L/min Lab Analysis, O₃, NDIR, Portable Gas Analyzers

- BD-05TVB: Dual-head design for smooth, stable flow. Versatile connections for higher flow or deeper vacuum. (7.2 L/min, -70 kPa in parallel)

- BD-05T067L: A powerful mid-range option with high vacuum capability, perfect for systems with significant flow resistance. (7 L/min, -85 kPa)

For 10–25 L/min High-Flow CEMS and Multi-Point Sampling

- BD-05T0910L: A high-flow workhorse with a long-life brushless motor, designed for continuous duty. (10 L/min, -85 kPa)

- BD-05T30K: Our ultimate performance pump for when you need maximum flow and deep vacuum. (25 L/min, -99 kPa)

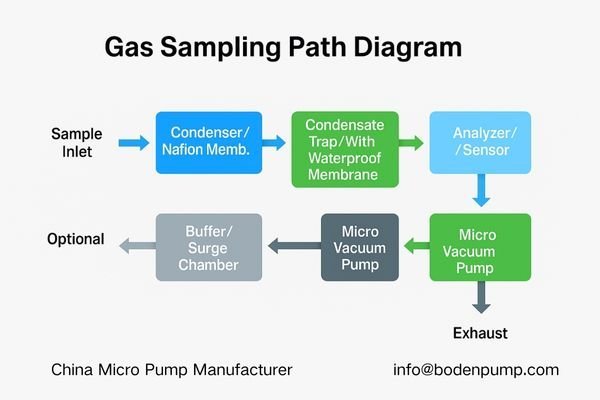

How to Design a Proper Sampling Path for Long Pump Life

You need a visual guide to put it all together. A clear diagram showing the correct sequence of components will help you avoid costly design mistakes.

The optimal sampling path is a logical sequence: always filter and dry the gas before it reaches the pump, and place the pump before the analyzer to avoid contaminating the sensor.

The Correct Component Sequence

To maximize the life of your pump and the accuracy of your sensor, arrange your gas path in this order:

- Sample Inlet

- 5 μm Pre-Filter (at the probe)

- Condenser / Nafion Membrane Dryer

- Condensate Trap / Water Separator

- 0.3 μm Fine Filter with Waterproof Membrane

- Buffer / Surge Chamber (optional, for flow stability)

- BODENFLO Micro Vacuum Pump

- Analyzer / Sensor (e.g., PID)

- Exhaust

This configuration ensures the pump receives only clean, dry gas and delivers a stable sample to your sensor.

FAQs: Common Questions from OEM Engineers

You still have a few specific questions. Getting clear answers to these common engineering challenges will give you the confidence to finalize your design.

Here are quick, direct answers to the questions I hear most often from OEM engineers designing gas sampling systems.

Q1: If we already have a filter, do we still need a dryer?

A: Yes. Filters only remove solid particles. They do not remove water vapor, which can condense inside the pump and cause corrosion and damage. You need both filtration and drying.

Q2: Can a pump run continuously with moisture in the gas?

A: No. While a small amount of vapor may pass through, continuous operation with humid gas will lead to condensation, diaphragm fatigue, corrosion, and a significantly shortened pump lifespan.

Q3: Do I need PTFE diaphragm pumps if the gas has SO₂/NO₂?

A: It depends on your pre-treatment. If you can effectively scrub or filter out these acid gases, a standard FKM pump may suffice. If not, then a pump with a full PTFE wetted path is the safest (but more expensive) choice.

Q4: How to choose between single-head and dual-head pumps?

A: Choose a dual-head pump (like our BD-05TVB) when you need higher flow, deeper vacuum (in series), or exceptionally low pulsation for a sensitive sensor. Single-head pumps are more compact and cost-effective for general use.

Q5: What is the minimum flow required for PID sensors?

A: This varies by sensor manufacturer, but it's typically in the range of 200 to 500 ml/min. Always check your specific PID sensor's datasheet.

Conclusion

Proper gas pre-treatment is the most critical investment you can make to ensure the long-term reliability of both your micro pump and your entire analytical instrument.

Investing in correct filtration and drying can easily double or triple your pump's operational lifespan. BODENFLO provides a full range of high-vacuum pumps for low, medium, and high-flow sampling systems, backed by engineering expertise to help you succeed.

Ready to build a more reliable gas sampling system? Send your requirements to info@bodenpump.com, and let our experts help you select the perfect pump.

-

Exploring best practices in gas sampling can enhance accuracy and reliability in your measurements. ↩

-

Exploring chemical corrosion will provide insights into material selection and maintenance for better pump longevity. ↩

-

Explore this link to understand how a 5 μm pre-filter enhances pump performance and protects against contaminants. ↩

-

Explore this link to understand how a 0.3 μm fine filter enhances pump performance and protects delicate components. ↩

-

Explore this link to understand how Condensers and Nafion Dryers enhance gas sampling by effectively removing moisture, ensuring pump longevity. ↩

-

Explore this link to understand the best materials for acidic gases, ensuring your pump's longevity and efficiency. ↩

-

Understanding flow rate requirements is crucial for selecting the right pump, ensuring optimal performance and efficiency. ↩