Your GC/MS system shows inconsistent results, and you suspect the sampling stage. An underperforming pump can ruin your entire analysis, but pinpointing it as the root cause is difficult.

A high vacuum pump is critical because it's the only component with enough force to pull a stable, precise air volume through a high-resistance sorbent tube. This guarantees accurate sample capture, which is the foundation for reliable GC/MS analysis and repeatable results.

As a project manager for OEM integrations, I've seen teams spend months troubleshooting complex GC/MS instruments. They blame the detector or the software, but often the real problem is much simpler: the sampling pump. It’s the engine of the entire system. If the engine is weak, the whole multi-million dollar setup fails. Let's break down why this small component has such a massive impact.

What Is GC/MS Sorbent Tube Sampling and How Does It Work?

Your team needs to capture trace gases accurately. You know sorbent tubes are the standard, but understanding the mechanics is key to designing a reliable system that delivers consistent results.

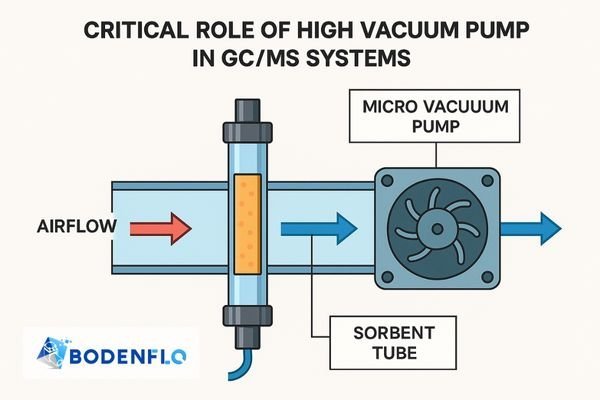

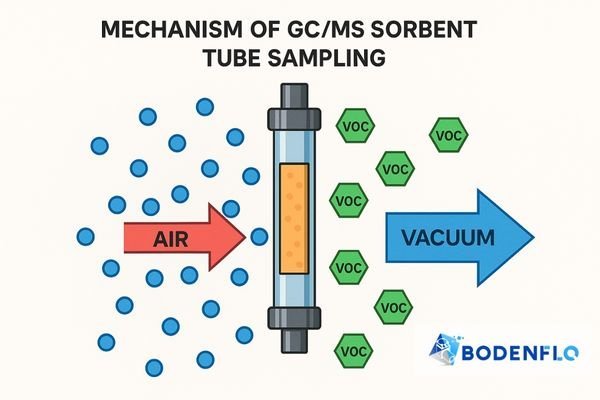

Sorbent tube sampling uses a vacuum pump to pull air through a tube filled with adsorbent material. This material traps target chemicals, like VOCs, for later analysis by a Gas Chromatograph/Mass Spectrometer (GC/MS).

The whole process is designed to concentrate tiny amounts of chemicals from the air into a sample that a GC/MS can easily detect. As an engineer, I think of it as a controlled, two-step operation.

Understanding GC/MS and Sorbent Tubes

Gas Chromatography/Mass Spectrometry (GC/MS)1 is a powerful analytical method. It separates complex chemical mixtures and identifies each component. Sorbent tubes are the preferred way to collect air samples for this analysis. The tube is a glass vial packed with a solid adsorbent material. This material has a high affinity for specific types of chemicals, especially Volatile Organic Compounds (VOCs)2.

The Role of Negative Pressure

The vacuum pump's job is to create negative pressure. This suction pulls a precise volume of air through the tube at a controlled flow rate. As the air passes, the sorbent material acts like a chemical sponge, trapping the target molecules. The accuracy of this adsorption process depends entirely on pulling a stable, known volume of air.

Typical Application Scenarios

This method is the gold standard in many industries. We see our pumps integrated into systems for:

- Environmental Monitoring: Measuring air pollution near factories.

- Workplace Safety: Testing worker exposure to industrial chemicals.

- Emission Testing: Verifying compliance for vehicle or factory exhaust.

- Odor Analysis: Identifying sources of nuisance odors in communities.

Why Is Vacuum Performance the Core Limiting Factor in Sorbent Tube Sampling?

You have sensitive detectors, but your data is still noisy or delayed. You might not realize that a weak vacuum pump is starving your sensors of a stable, representative gas sample.

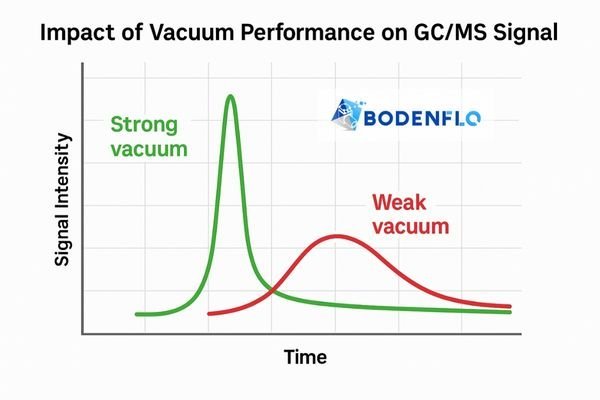

Vacuum performance is the core limiting factor because it dictates the stability and speed of sample delivery. Insufficient vacuum force leads to sample loss and delayed response times, directly compromising the accuracy of GC/MS analysis.

In every project, I emphasize that the pump is not just an accessory; it is the heart of the fluidic system. A GC/MS detector is passive. It can only analyze the sample that is delivered to it.

Why Sensors Cannot Pull Gas

Highly sensitive detectors3 and sensors have no ability to draw in a gas sample on their own. They rely completely on an external pump to create the necessary flow. The sample must be actively pulled from the source, through the sorbent tube, and into the analyzer.

Vacuum Force and Sampling Stability

The "force" of the vacuum directly relates to the stability of the sample flow. A strong, deep vacuum acts like a powerful buffer against any changes in system resistance. This ensures a rock-solid, non-pulsating flow of gas. A weak vacuum, however, is easily affected by small changes, causing the flow to fluctuate.

Consequences of Weak Vacuum

When the vacuum is weak, several problems occur:

- Sampling Loss: The pump can't pull the full required volume, so the final concentration reading is artificially low.

- Dilution: Ambient air might leak into the sample path if the pump can't maintain sufficient negative pressure.

- Delayed Response: The system takes longer to draw the sample to the detector, smearing out the analytical peaks and reducing sensitivity.

Ultimately, the stability of the vacuum pump's performance is the primary factor determining the accuracy of the final GC/MS detection.

Why Is High Vacuum Required for Sorbent Tube Applications?

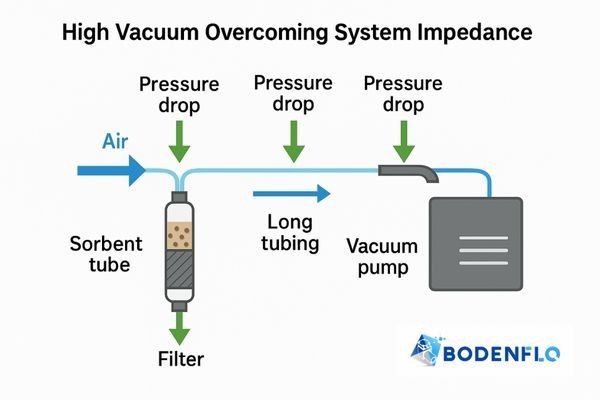

You've selected a pump that meets the flow rate on paper, but in the real system, it fails. This is often because the high resistance of sorbent tubes and filters was not accounted for.

High vacuum is required to overcome the significant flow resistance, or impedance, created by tightly packed sorbent materials, filters, and long tubing. It provides the power needed to maintain flow against this back pressure.

A common mistake I see engineers make is underestimating the total system resistance. The pump isn't just moving air; it's pulling air through a series of obstacles.

High Flow Resistance from Sorbents

The sorbent material inside the tube is like very fine sand. It's tightly packed to maximize surface area for adsorption. This dense packing creates a very high resistance to airflow. Trying to pull air through it is like trying to drink a thick milkshake through a narrow straw.

Pressure Drop from Filters and Tubing

In addition to the sorbent tube, a real-world system always includes micro-filters to protect the pump and analyzer. It also has tubing connecting all the components. Each of these adds to the total pressure drop. The longer the tubing and the finer the filter, the greater the resistance.

Overcoming Back Pressure

A high vacuum pump is designed to handle this. It can generate a very low absolute pressure, creating a large pressure differential across the system. This powerful "pull" easily overcomes the combined back pressure from the tube, filter, and tubing, ensuring a stable flow rate. Low-vacuum pumps simply don't have this strength. They stall or fail when faced with a real system load.

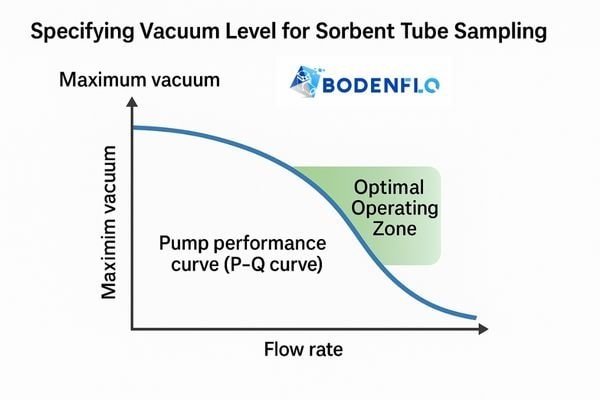

What Vacuum Level Is Actually Required for GC/MS Sorbent Tube Sampling?

You know you need "high vacuum," but what does that mean in specific numbers? Choosing a pump with the wrong vacuum spec—either too low or excessively high—can cause performance issues and unnecessary cost.

For most sorbent tube systems, a working vacuum in the range of -65 kPa to -85 kPa is needed. This requires a pump with a maximum ultimate vacuum of -85 kPa or more to ensure stability.

Specifying the vacuum level correctly is a critical design step. It's about matching the pump's capability to the system's demand.

Defining Your Working Vacuum

First, don't confuse maximum vacuum with working vacuum4. Maximum (or ultimate) vacuum is the deepest vacuum the pump can achieve with zero flow. The working vacuum is the pressure level while pulling your target flow rate. For most sorbent tube applications, this working point is between -65 kPa and -85 kPa.

Matching Vacuum to Flow Requirements

The required vacuum level depends on the flow rate and the system's resistance. A higher flow rate or a more resistant sorbent tube will require a deeper working vacuum. You must select a pump that can comfortably provide this vacuum without running at its absolute limit. A pump running at its maximum capacity is unstable and will fail prematurely.

Consequences of Incorrect Sizing

| Sizing Error | Consequence |

|---|---|

| Undersizing (Too Low Vacuum) | The pump cannot overcome system resistance. This leads to unstable or insufficient flow, causing inaccurate sampling and failed analyses. |

| Oversizing (Excessive Vacuum) | The pump is larger, more expensive, and consumes more power than necessary. Without proper flow control, it can also damage the sorbent material or exceed its maximum sampling rate. |

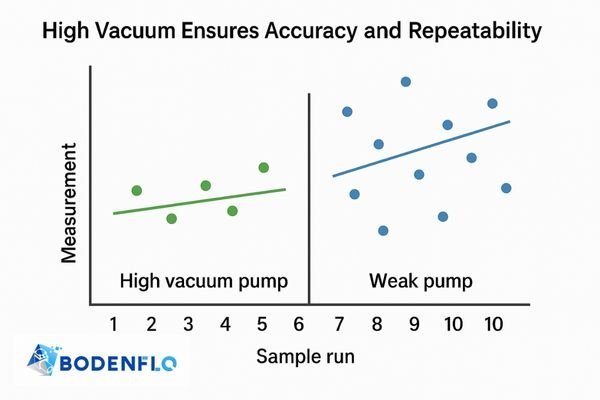

How Does High Vacuum Improve Sampling Accuracy and Repeatability?

Your goal is not just one accurate measurement, but hundreds of repeatable ones. You need to eliminate any variables in the sampling process that could compromise the integrity of your quantitative analysis.

A high vacuum pump improves accuracy by maintaining a constant flow rate even when resistance changes. This ensures a consistent sample volume is collected every time, which is the foundation of repeatable quantitative analysis.

Accuracy and repeatability are what separate a research-grade instrument from an unreliable one. Here is how a powerful vacuum pump directly contributes to both.

Constant Flow Under Changing Conditions

During sampling, environmental conditions can change. Dust might start to clog a filter, or temperature changes can affect gas density. A pump with a deep vacuum has the reserve power to automatically compensate for these changes, keeping the flow rate locked in.

Preventing Breakthrough

Every sorbent material has a maximum flow rate. If the flow spikes too high, the target molecules don't have enough time to be adsorbed and pass straight through the tube. This is called "breakthrough" and it invalidates the sample. A stable pump prevents these flow spikes.

Consistent Sample Volume

Quantitative analysis depends on this formula: Concentration = Mass of Analyte / Volume of Sample. The GC/MS measures the mass. Your system must guarantee that the volume is the same for every single run. Only a high-performance vacuum pump can provide this level of consistency.

Reducing Noise and Drift

An unstable flow can introduce noise into the detector's baseline signal. A powerful and stable vacuum pump provides a smooth, laminar flow, which helps reduce measurement drift and lowers the overall detection limit of the instrument.

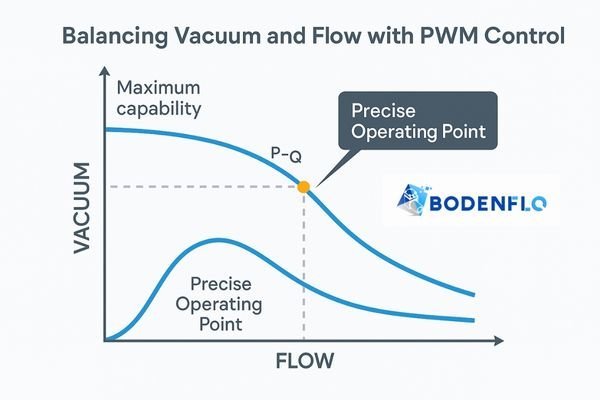

Why Is Flow Stability as Important as High Vacuum in GC/MS Sampling?

You've chosen a pump with a very deep vacuum, but your flow is still unstable. This is because high vacuum alone is not enough; it must be paired with precise flow control.

Flow stability is crucial because excessive vacuum without control can cause flow rates to exceed the sorbent's capacity, leading to sample breakthrough. A balanced pump curve and PWM control are needed to achieve stable flow.

In my experience, the best instrument designs are the ones that balance vacuum power with flow precision. One without the other is a recipe for failure.

The Vacuum–Flow Balance

Every pump has a performance curve (P-Q curve)5 that shows the relationship between pressure (vacuum) and flow (quantity). A pump with a deep vacuum but a steep, unstable curve is a poor choice. An ideal sampling pump has a relatively flat curve in the desired operating range, meaning the flow rate changes very little even as the vacuum level fluctuates.

The Danger of Uncontrolled Vacuum

Imagine connecting a massively oversized vacuum pump directly to a sorbent tube. The immense suction would pull air through so fast that no adsorption could occur. It could even physically damage the delicate sorbent bed. Power must be controlled.

PWM Control for Stability

This is where Pulse Width Modulation (PWM) control6 is essential. By sending a digital signal to a brushless DC motor, you can adjust the pump's speed with incredible precision. This allows the system's software to create a feedback loop, constantly adjusting the pump speed to maintain a rock-solid flow rate, regardless of changes in back pressure. This active control delivers the ultimate stability.

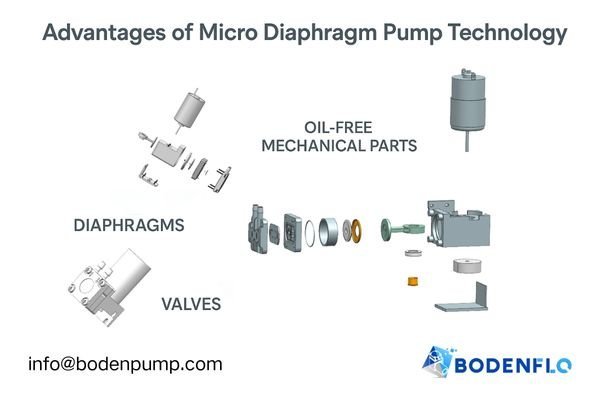

Why Are Micro Diaphragm Vacuum Pumps the Preferred Choice for GC/MS Sampling?

You need to select a pump technology. With options like rotary, piston, and diaphragm pumps available, you must choose the one that meets the specific, demanding requirements of trace gas analysis.

Micro diaphragm pumps are the preferred choice due to their oil-free operation, excellent chemical compatibility, and stable performance. They provide clean, contaminant-free sampling in a compact, maintenance-free package, unlike other pump types.

When designing high-sensitivity analytical instruments, the choice of pump technology is critical. Diaphragm pumps7 have become the industry standard for very specific reasons.

Key Advantages of Diaphragm Technology

The core of the pump is a flexible diaphragm that moves up and down. This simple, elegant design provides several key benefits:

- Oil-Free Operation: The pumping mechanism is completely isolated from the motor bearings. This guarantees that no oil lubricants can contaminate the gas sample, which is absolutely critical for trace analysis.

- Maintenance-Free: There are no sliding seals that wear out or require lubrication. Our diaphragm pumps are designed for tens of thousands of hours of continuous, trouble-free operation.

- Excellent Chemical Compatibility: We can make the wetted parts (head, diaphragm, and valves) from different materials like EPDM, Viton (FKM), or Teflon (PTFE) to handle a wide range of corrosive or reactive gases safely.

Why Other Pumps Are Less Suitable

In contrast, other pump technologies have significant drawbacks for this application.

| Pump Type | Drawbacks for Trace Gas Analysis |

|---|---|

| Rotary Vane Pumps | Use oil for sealing and lubrication. Guaranteed sample contamination. Bulky and require frequent maintenance. |

| Piston Pumps | Often use oil-lubricated rings. Even "oil-free" versions have wearing seals that can generate particulate contamination. Can have high pulsation. |

Which High Vacuum Micro Pumps Are Suitable for GC/MS Sorbent Tube Systems?

You understand the technology and are ready to select a specific pump series. You need a model that is compact, powerful, and controllable, suitable for integration into either a portable or a benchtop instrument.

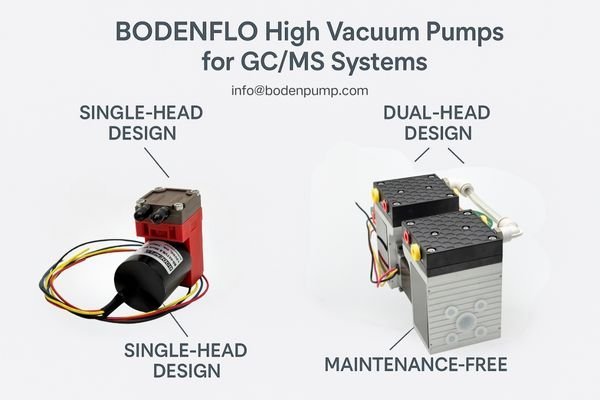

PWM-controllable, dual-head diaphragm pumps, like the BODENFLO C60-V series, are ideal. They provide deep vacuum, stable flow, and the precise control needed for both portable and fixed GC/MS systems.

When our OEM clients ask for recommendations, we guide them based on their specific application needs. The choice often comes down to balancing size, power, and control features.

For Portable Systems: Small-Size Pumps

For handheld or portable field units, size and power consumption are critical. A compact, single-head pump with high efficiency is often the best choice. It provides sufficient vacuum for most standard applications in a lightweight package that is ideal for battery operation.

For Benchtop Systems: Dual-Head Pumps8

For high-performance laboratory instruments, a dual-head diaphragm pump is the standard. The two heads work in sequence or in parallel. This design offers two key advantages:

- Deeper Vacuum: They can achieve much deeper ultimate vacuum levels (e.g., -92 kPa).

- Lower Pulsation: The overlapping pumping cycles create a much smoother, more stable airflow.

PWM-Controllable Pumps for Precision9

For any high-end analytical system, I always recommend a pump with a brushless DC motor and PWM speed control. This feature gives the instrument's designer complete control over the pump's performance. It allows them to fine-tune the flow rate and build sophisticated feedback loops, resulting in superior analytical precision. This is a must-have for modern GC/MS design.

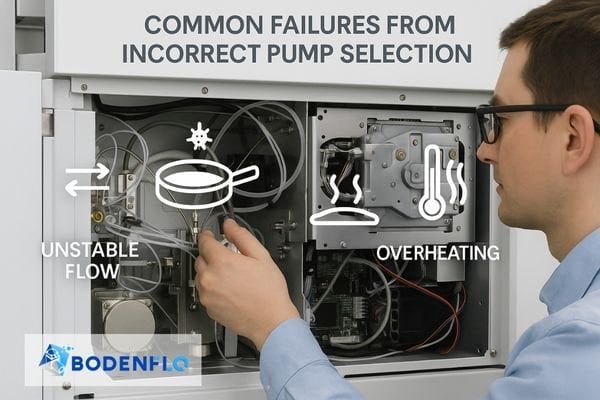

What Are the Most Common GC/MS Sampling Failures Caused by Incorrect Vacuum Pump Selection?

Your instrument is failing in the field. Understanding the common failure modes and linking them back to an incorrect pump choice is the key to creating a more robust and reliable system design.

The most common failure is insufficient vacuum leading to unstable flow and inconsistent sample volumes. Other critical issues include pump-generated contamination, overheating, and excessive vibration that interferes with sensitive detectors.

During the design phase, I always push our partners to think about failure modes. Choosing a cheap or incorrectly specified pump is a leading cause of instrument downtime and unreliable performance. Here are the top five failures I see.

- Insufficient Vacuum: The number one problem. The pump can't handle the real-world system impedance, causing the flow to drop. This leads directly to repeatability errors because the sample volume is never the same.

- Pump Contamination: This happens when a non-diaphragm pump is used, or a diaphragm pump is made from the wrong materials. It introduces artifacts into the sample, affecting chromatographic accuracy10 and leading to false positives.

- Overheating and Failure: A pump that is too small for the job will be forced to run at 100% capacity continuously. This leads to overheating, which degrades the diaphragm and bearings, causing premature pump failure.

- Noise and Vibration11: Low-quality pumps are often poorly balanced. The mechanical vibration can travel through the instrument chassis and interfere with highly sensitive mass spectrometer detectors, increasing background noise.

- Inconsistent Sampling Volumes: A direct result of an unstable pump. This is the most frustrating error because it makes it impossible to perform reliable quantitative analysis.

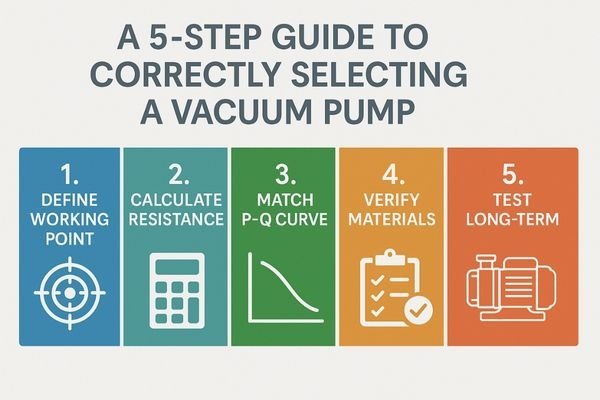

How Do You Correctly Select a High Vacuum Pump for Your GC/MS System?

You want a straightforward process for choosing the right pump. You need a practical checklist to ensure you consider all the critical parameters, from performance curves to material compatibility, for a successful integration.

Correctly selecting a pump involves matching the pump's P-Q curve to your system's required working point (flow and vacuum), not just its maximum rating. You must also verify chemical compatibility and prioritize long-term stability.

To avoid the failures we just discussed, I walk my clients through a rigorous 5-step selection process. This ensures we choose a pump that is not only powerful enough but also reliable for the life of the instrument.

- Define Required Working Point: Don't start with the maximum vacuum. Start with your target. For example, "I need to pull 200 mL/min of air through sorbent tube model XYZ."

- Calculate System Resistance: Measure the actual pressure drop of your tube, filters, and tubing at that target flow rate. This will give you your true working vacuum requirement (e.g., -75 kPa).

- Match Pump P-Q Curve: Now, look at the pump's performance curve. The pump you choose should be able to deliver 200 mL/min at -75 kPa while operating in the middle of its curve, not near its limit. This provides a crucial stability margin.

- Verify Chemical Resistance12: Confirm that all the wetted materials (pump head, diaphragm, valves) are compatible with the gases you are sampling. This prevents corrosion and contamination.

- Consider Long-Term Stability: Ask for long-term test data. A pump's performance can degrade over time. A high-quality pump will demonstrate stable performance over thousands of hours, ensuring the instrument remains calibrated and reliable.

What Are Some Real Application Scenarios of High Vacuum Pumps in GC/MS Sorbent Tube Sampling?

You understand the technical details. Now, let's look at where this technology is deployed. Seeing real-world examples helps demonstrate the critical role these pumps play in protecting health and the environment.

High vacuum pumps are the engine for GC/MS sampling in environmental monitoring stations, industrial emissions testing, occupational safety assessment, indoor air quality analysis, and portable field detection equipment.

The reliability of our pumps is trusted in some of the most demanding analytical applications. Here are a few examples of systems where our high vacuum pumps are currently in use.

- Environmental Air Monitoring Stations: Unattended stations running 24/7 to detect urban pollutants. The pump's long, maintenance-free life is essential here.

- Industrial VOC Emission Monitoring: Continuous Emission Monitoring Systems13 (CEMS) installed on factory smokestacks require powerful, robust pumps to handle hot and dirty gas streams.

- Occupational Exposure Testing: Small, battery-powered personal sampling pumps worn by workers in chemical plants. These pumps must be lightweight, reliable, and intrinsically safe.

- Indoor Air Quality Analysis: Consultants use portable instruments to check for mold, formaldehyde, and other "sick building" contaminants. The pump's quiet operation is a key advantage.

- Portable GC/MS Field Equipment: Used by hazmat teams or the military to rapidly identify unknown chemical threats. In this scenario, the pump's speed and reliability can be life-saving.

Why Is BODENFLO a Leading Micro Vacuum Pump Manufacturer in China for GC/MS Sampling Systems?

You need more than just a component supplier; you need an expert partner. You want a manufacturer with deep technical knowledge, proven experience, and the capability to support your project from prototype to production.

BODENFLO is a leader because we focus exclusively on high-vacuum micro diaphragm pump R&D and have extensive experience in OEM projects for analytical instruments like GC/MS. Our in-house capabilities and quality control ensure superior, reliable performance.

Many companies can sell pumps. At BODENFLO, our goal is to provide engineered solutions. Global analytical instrument manufacturers partner with us because we offer a level of specialization that is rare in the industry.

Core Strengths in High Vacuum Technology

Our R&D is laser-focused on pushing the boundaries of what's possible in a small diaphragm pump. We have core technology advantages in achieving deep vacuum levels, from -85 kPa down to -100 kPa, while maintaining stability and long life.

Proven OEM Project Experience

We have a strong track record of success in projects for GC, GC/MS, CEMS, and PID gas analyzers. We understand the unique challenges of this industry, from sample purity to signal-to-noise ratios.

Comprehensive In-House Capabilities

We control every aspect of pump performance:

- Motor Matching: We design and match our own high-efficiency brushless motors.

- Diaphragm Material Science: We select and test the optimal elastomer compounds for chemical resistance and longevity.

- EMC Control: We ensure our pumps meet strict electromagnetic compatibility standards to avoid interfering with sensitive detectors.

- Lifetime Testing: Our labs run pumps for thousands of hours to validate their long-term stability.

Our ISO 9001-certified quality system and our experience working with top OEM partners in Europe and the US make us a reliable, trusted choice for your next GC/MS project.

Conclusion

Selecting the right high vacuum pump is the most critical decision for ensuring GC/MS sampling accuracy. Partner with an expert. Contact the BODENFLO team at info@bodenpump.com to optimize your instrument’s design.

-

Explore this link to gain a deeper understanding of GC/MS, its applications, and its significance in analytical chemistry. ↩

-

Learn about VOCs, their impact on health and the environment, and why monitoring them is crucial for safety. ↩

-

Exploring how sensitive detectors function will deepen your insight into gas analysis techniques and their applications. ↩

-

Understanding working vacuum is essential for optimizing pump performance and ensuring accurate results in applications. ↩

-

Learn about the P-Q curve to grasp how pressure and flow interact, crucial for selecting the right pump. ↩

-

Explore this link to understand how PWM control enhances precision and stability in pump systems. ↩

-

Explore this link to understand why diaphragm pumps are essential for high-sensitivity analytical instruments. ↩

-

Discover the unique benefits of dual-head pumps, including deeper vacuum and lower pulsation, essential for high-performance labs. ↩

-

Explore this link to understand how PWM technology enhances precision in analytical systems, crucial for modern applications. ↩

-

Exploring this topic will help you grasp the importance of pump selection in achieving reliable chromatographic results. ↩

-

Understanding the impact of noise and vibration can help improve instrument performance and data accuracy. ↩

-

Exploring chemical resistance verification methods helps prevent equipment failure and ensures compatibility with your specific applications. ↩

-

Learn about CEMS and their role in monitoring emissions, ensuring compliance, and protecting the environment. ↩