In the modern world, we face the growing pressure to make everything smaller, lighter, yet more powerful—this is especially true in the pump industry. How small can a vacuum pump be while still being functional?

The short answer is "quite small"—advancements in microtechnology and materials have made it possible to create compact vacuum pumps that are just a few inches in size but don't compromise on performance.

As the Project Manager at BODENFLO, I've seen firsthand how miniature pump technology is transforming the industry. Stick around as we delve deeper into this fascinating topic.

What Drives the Need for Smaller Vacuum Pumps?

The Push for Portability

One of the biggest factors driving the need for smaller vacuum pumps is the push for portability, particularly in the medical and aerospace sectors. In these fields, the need to save space while maintaining or even increasing efficiency is crucial. Portable medical devices like handheld aspiration units, for instance, need to be lightweight and compact, making smaller vacuum pumps a requirement rather than an option.

Industry-Specific Needs

In industrial settings, small vacuum pumps are often needed for specialized applications where a large pump would be impractical. These could include automated machinery or robotics, where every inch of space is valuable. The ability to integrate a compact vacuum pump directly into the machinery can be a game-changer in terms of performance and space optimization.

Regulatory Factors

Regulatory compliance is another aspect that's fueling this shift toward smaller sizes. With increasing environmental regulations, companies are under pressure to minimize their carbon footprint. Compact vacuum pumps often consume less power, aligning with eco-friendly business practices.

The IoT and Connectivity

Lastly, as the Internet of Things (IoT) expands, the requirement for vacuum pumps to be not only small but also smart is becoming more apparent. Smaller vacuum pumps can be easily integrated into IoT systems, providing real-time data that can help in predictive maintenance and efficiency optimization.

The demand for vacuum pump small size is influenced by a variety of factors including the push for portability, industry-specific needs, regulatory compliance, and the integration possibilities with IoT. All of these contribute to making miniaturization not just a trend, but an industry necessity.

Do Small Vacuum Pumps Maintain Efficiency?

Engineering Breakthroughs

One might assume that downsizing a vacuum pump could lead to a compromise in performance. However, engineering advancements have proved otherwise. Innovations in material science and mechanical engineering have enabled the creation of compact pumps that can deliver performance comparable to, or even exceeding, their larger counterparts. Our pumps at BODENFLO, for example, utilize highly advanced diaphragms and specialized motors to ensure peak efficiency.

Material Matters

The type of materials used plays a crucial role in maintaining the efficiency of smaller vacuum pumps. High-quality metals and polymers can withstand greater stress, thereby maintaining optimum performance over time. Through extensive R&D, we've optimized our material selection to offer robust and efficient vacuum pumps that meet the stringent demands of various industries.

Efficient Design

Another contributing factor to efficiency is the design of the pump itself. More intelligent designs have surface enhancements, and fluid dynamics optimized to improve overall performance. These designs often feature better heat dissipation mechanisms, allowing the smaller pump to handle similar or higher workload levels compared to larger models without overheating.

Data-Driven Optimization

The advent of smarter, more connected devices also allows for real-time performance monitoring. This data can be invaluable for predictive maintenance and efficiency optimization, ensuring that even the micro vacuum pumps operate at peak levels at all times. This connectivity further enhances their value proposition, making them not just space-saving but also functionally superior in many respects.

Modern small vacuum pumps have shattered the preconceived notion that 'bigger is better,' by proving that efficiency and performance can indeed be maintained or even improved in a more compact form.

How Does Miniaturization Impact Cost?

Initial Capital Expenditure

At first glance, one might expect that a smaller vacuum pump would be less expensive due to reduced material costs. However, this isn't necessarily the case. The intricate designs and specialized components often required for miniaturized pumps can significantly increase the initial capital expenditure. For instance, high-performance materials such as titanium or carbon composites may be needed to withstand high pressure and temperature conditions, thereby driving up costs.

R&D Investment

Additionally, significant investments in research and development are needed to achieve the same, or better, performance in a smaller package. This is particularly true for custom solutions tailored to specific industry needs, where a simple downscaling of existing designs is not feasible. At BODENFLO, our commitment to R&D ensures that we offer optimized, efficient pumps irrespective of their size.

Long-Term ROI

While the initial investment may be higher, it’s crucial to consider the long-term return on investment (ROI). Miniaturized pumps often offer higher operational efficiency and lower maintenance costs, translating to lower total cost of ownership over the pump's lifetime. Their smaller footprint also means that they require less storage space, providing additional indirect savings.

Economies of Scale

Another factor that can influence cost is the economies of scale. As the demand for smaller, more efficient vacuum pumps increases, it's likely that the cost per unit will decrease. Increased production volumes often lead to optimized manufacturing processes, which can help to offset the higher initial development costs.

While the upfront cost of miniaturized vacuum pumps may be higher due to the specialized materials and technologies involved, the long-term benefits often justify the investment, making them a cost-effective choice for many applications.

What About Durability and Longevity?

Material Selection Matters

One might think that smaller pumps compromise on durability. However, that's far from the truth. The key to durability lies in the choice of materials. At BODENFLO, we use high-grade metals like stainless steel and specialized plastics such as PEEK (Polyether Ether Ketone) to construct our vacuum pumps. These materials offer superior resistance to wear and tear, chemical corrosion, and high temperatures.

Rigorous Testing Protocols

Beyond materials, the testing protocols to which these pumps are subjected are second to none. Whether it’s pressure endurance, thermal cycling, or vibration testing, our micro vacuum pumps undergo a series of rigorous tests to ensure they meet or exceed industry standards. Our dedicated team of engineers continually evaluates the test results to refine our designs further, enhancing the product’s lifespan.

Operational Factors

Longevity isn’t just about surviving harsh conditions; it’s about maintaining optimal performance throughout the pump’s life. Even under constant usage or challenging environmental factors like high humidity or extreme temperatures, our micro vacuum pumps continue to operate efficiently. This resilience adds to their value proposition, making them not just a short-term solution but a long-term investment.

Safety Mechanisms

Moreover, modern small vacuum pumps often come equipped with built-in safety mechanisms, such as overheating protection or auto-shutdown features. These safeguards not only prolong the life of the pump but also protect the systems they are integrated into.

when it comes to durability and longevity, smaller vacuum pumps designed with high-quality materials and subjected to rigorous testing can certainly stand toe-to-toe with their larger counterparts. At BODENFLO, we're committed to providing robust and efficient solutions, no matter the size.

How Do You Choose the Right Miniature Vacuum Pump?

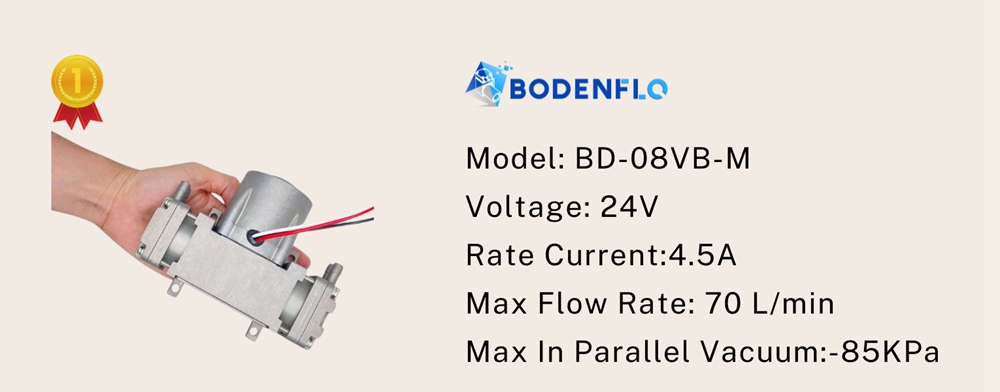

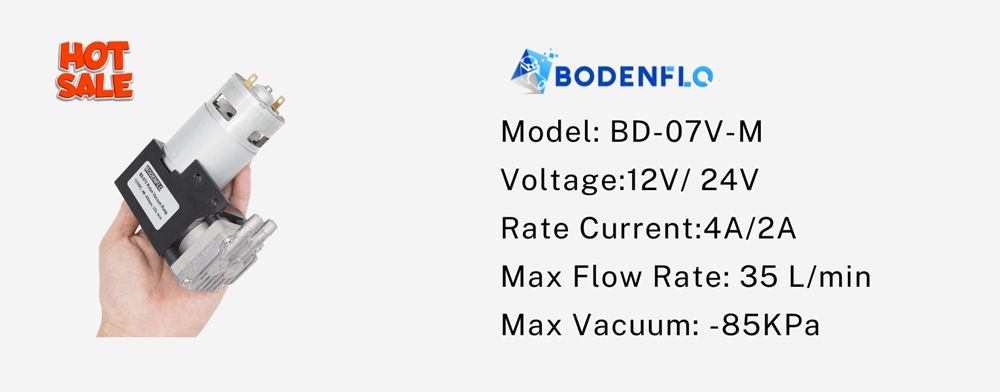

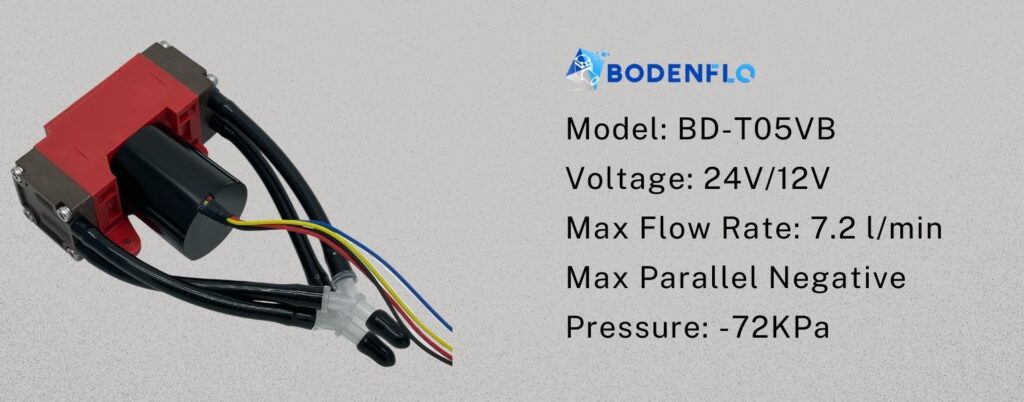

Understanding Specifications

The first step in choosing the right vacuum pump is having a deep understanding of your specific application requirements. This involves considering critical specifications such as flow rate, vacuum level, and operating pressure. By understanding these key performance indicators, you're already one step closer to making an informed decision.

Consult with Experts

Next, always consult with experts in the field or specialized engineers who can guide you through the selection process. They can offer insights that may not be immediately obvious, like compatibility with existing systems, energy efficiency, or maintenance needs.

Application Setting

It's crucial to understand the environment in which the pump will operate. Is it a cleanroom or a harsh industrial setting? Will it be used in a mobile application? This will influence the type of pump you need. For instance, pumps used in medical applications often need to meet more stringent sanitation and noise-level criteria than those used in industrial settings.

Customizable Solutions at BODENFLO

Finally, if you're still unsure, don't hesitate to reach out to us at BODENFLO. We specialize in providing parametric customizable and OEM solutions that can be tailored to your specific needs. By collaborating with our team of skilled engineers, we can develop a pump that not only meets but exceeds your requirements.

Choosing the right vacuum pump can be a complex process, but with the correct guidance and a focus on specifics, you'll find exactly what you need. At BODENFLO, we're committed to helping you navigate these choices to find the ideal pump for your application.

What's the Future of Miniature Vacuum Pumps?

Technological Advancements

The future of miniature vacuum pumps is intrinsically tied to technological advancements. As materials science progresses, we can anticipate pumps made from novel alloys or composites that are not only lighter but also more durable. Advances in motor technology and control systems will likely make these pumps more energy-efficient, reducing the overall cost of ownership.

IoT and Smart Technologies

Internet of Things (IoT) and smart technologies are set to revolutionize the way we interact with and control vacuum pumps. Remote monitoring and predictive maintenance powered by AI algorithms can further extend the lifespan of these devices. This would be particularly beneficial in critical applications such as healthcare and aerospace, where equipment downtime can have severe consequences.

Application-Specific Innovations

As the range of applications for miniature vacuum pumps broadens, we can expect more specialized models to come into the market. For instance, pumps designed explicitly for medical applications might incorporate antibacterial surfaces or offer ultra-low noise levels for patient comfort.

Global Trends

With an increasing focus on sustainability, future miniature vacuum pumps will likely need to meet higher environmental standards. This could involve everything from the materials used in manufacturing to the energy efficiency of the pump itself.

The future indeed looks bright for miniature vacuum pumps. Continuous innovations in engineering and technology promise a new generation of smaller, more efficient, and more specialized vacuum pumps. At BODENFLO, we're excited about these developments and are committed to being at the forefront of this technological revolution.

Conclusion

Size doesn't dictate performance or durability when it comes to modern vacuum pumps. Thanks to technological advancements, we can enjoy compact, efficient, and robust vacuum pumps suited for various applications.

Explore the technological possibilities with BODENFLO's range of vacuum pumps. Contact us today at info@bodenpump.com to discover the perfect pump that aligns with your specific needs.