Medical devices often need precise suction, but getting it in a compact design is a challenge. Without it, patient care can suffer. The purpose is creating controlled negative pressure.

A medical vacuum pump's main purpose is to remove air or fluids from a patient or a sealed medical environment. This controlled suction is essential for procedures like wound therapy, respiratory support, surgical aspiration, and diagnostic sampling, ensuring treatments are safe and effective.

When I first started at BODENFLO, I thought of vacuum pumps as industrial tools used in manufacturing. But I quickly learned that our miniature diaphragm pumps are the silent, beating hearts inside some of the most advanced medical devices. Seeing how our technology directly contributes to patient healing and diagnosis is incredibly motivating. The reliability of these tiny pumps is not just a performance metric; it's a critical component of patient safety and a testament to the importance of precision engineering in healthcare.

What are the Main Clinical Applications for Medical Vacuum Pumps?

You know suction is used in hospitals, but the sheer variety of applications can be surprising. It's hard to grasp how one core technology can be adapted to so many different medical needs.

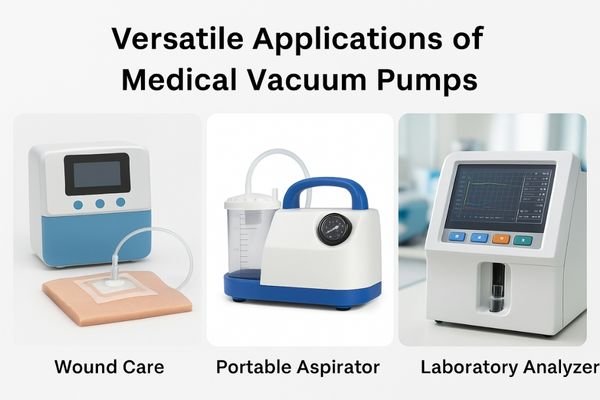

Miniature medical vacuum pumps are used across healthcare, from promoting healing in wound care to enabling accurate results in diagnostic machines. Their versatility makes them a core component in both hospital and portable medical equipment.

The pump's role changes dramatically depending on the device. For instance, in a blood pressure monitor, the pump is used for precise inflation and controlled deflation of the cuff. In a diagnostic sampler, it must pull an exact micro-volume of fluid without causing damage to the sample. This requires incredible precision and consistency. In contrast, a respiratory aspirator needs high flow to act quickly. Understanding the specific task—whether it's gentle and sustained or fast and powerful—is the first step in seeing how a miniature pump fits into the larger picture of patient care.

Key Medical Pump Applications

| Application | Primary Function | Key Pump Requirement |

|---|---|---|

| Negative Pressure Wound Therapy1 | Removes fluid from a sealed wound to promote healing. | Stable vacuum, long life |

| Respiratory Aspirators | Clears mucus and fluids from a patient's airway. | High reliability, fast action |

| Diagnostic Sampling (IVD)2 | Pulls blood or reagent samples into an analysis machine. | Precision, consistency |

| Surgical Smoke Evacuation | Removes harmful smoke and aerosols from the operating field. | High flow rate |

How Do Pumps Enable Negative Pressure Wound Therapy (NPWT)?

Chronic wounds can fail to heal on their own, leading to serious complications. Traditional dressings are often not enough to manage fluid and stimulate tissue growth effectively.

In NPWT, a miniature vacuum pump creates a gentle, continuous suction under a sealed dressing. This removes excess fluid, reduces swelling, and promotes blood flow, dramatically accelerating the healing process.

The pump is the engine of an NPWT system. Its most critical job is to maintain a very stable sub-atmospheric pressure3, typically around -20 kPa to -80 kPa, for 24 hours a day, sometimes for weeks. Any fluctuation can cause patient discomfort or reduce the therapy's effectiveness. This is where pump reliability4 and long life are not just features, but absolute necessities. The pumps in these devices must be exceptionally quiet and compact, as patients often wear them in portable units to maintain their mobility. It's a perfect example of advanced technology directly improving a patient's quality of life during recovery.

What is the Pump's Role in Surgical and Respiratory Suction?

During surgery or a medical emergency, a patient's airway can become blocked by fluids. This is a critical situation where every second counts, and manual methods are too slow and inefficient.

A vacuum pump powers aspirators and suction devices that quickly and effectively clear a patient's airway or a surgical site. This ensures a doctor can see clearly and the patient can breathe without obstruction.

In these applications, the pump's most important characteristic is its ability to generate a high flow rate5 on demand. A portable aspirator, for example, might sit idle for hours but must provide powerful suction the instant it is turned on. The design must be robust enough to handle thick fluids without clogging or losing performance. This is also true for surgical smoke evacuators6, which protect the operating room staff from inhaling harmful airborne particles. The pump provides a constant, high-volume flow of air to capture the smoke at its source. For these devices, power, speed, and reliability are the top priorities.

What Critical Standards Define a Pump as 'Medical-Grade'?

Assuming every medical pump needs FDA approval can stop your project cold. This belief leads to over-engineering and unnecessary costs, especially for diagnostic equipment, where the standards are different.

The required standards depend entirely on the application. For devices with direct patient contact, strict biocompatibility is mandatory. For in-vitro diagnostic (IVD) devices, the focus is on reliability, precision, and preventing sample contamination, governed by a robust quality system like ISO 9001.

The term 'medical-grade' is not one-size-fits-all. A pump going into a respiratory device that a patient breathes from has a completely different set of risks than a pump moving reagents inside a sealed lab machine. The latter doesn't need to be built in a Class 8 cleanroom, but it does need incredible consistency to ensure test results are accurate every time. At BODENFLO, our UKAS ISO9001:2015 quality system is perfect for delivering the batch-to-batch consistency required for IVD applications7, while our expertise in material science helps our clients select biocompatible components8 for their direct-contact devices.

Differentiating 'Medical' Application Standards

| Standard Focus | Direct Patient Contact (e.g., Wound Therapy) | In-Vitro Diagnostic (IVD) (e.g., Lab Analyzer) |

|---|---|---|

| Primary Goal | Patient Safety: Prevent harm, infection, or irritation. | Test Result Accuracy: Prevent sample contamination or error. |

| Material Requirements | Biocompatible materials for all wetted parts. | Chemically inert materials to not react with the sample. |

| Governing Standard Example | Final device may require FDA/MDR approval. | Focus on reliability under a quality system like ISO 9001. |

| Biggest Risk of Failure | Direct harm to the patient. | Inaccurate diagnostic results. |

Why is Oil-Free Diaphragm Technology Ideal for Medical Use?

Many pump types rely on oil for lubrication, creating a risk of contamination. They are also often heavy, complex, and require frequent maintenance, making them unsuitable for modern, portable medical devices.

A diaphragm pump uses a flexible membrane to generate suction, completely isolating the mechanical parts from the fluid path. This inherently oil-free, compact, and efficient design is the perfect solution for safe and reliable medical applications.

The elegance of the diaphragm pump9 lies in its clean and simple mechanics. The only parts that ever touch the medical fluid or gas are the pump head, the diaphragm, and the valves. This makes it incredibly easy for us to ensure biocompatibility10 or chemical inertness by simply selecting the right materials for these few components. This sealed design not only guarantees oil-free operation but also results in a pump that is lightweight, consumes very little power, and requires no maintenance over its long lifespan. These combined benefits make diaphragm technology the gold standard for both patient-contact and IVD devices.

How Do You Select the Right Pump for Your Medical Device?

You know you need a pump, but facing rows of technical specifications is overwhelming. Choosing the wrong model can lead to poor device performance, costly redesigns, and significant project delays.

To select the right pump, you must first define your four critical parameters: the required vacuum level, the necessary flow rate, power consumption limits, and the expected operational lifespan for your specific device.

I always advise our clients to start with these four specifications. They act as a filter that quickly narrows down the options from hundreds to just a few. For instance, a battery-powered NPWT device needs a pump with a stable vacuum level and extremely low power draw. A lab analyzer, on the other hand, requires an exceptionally long operational life and high precision. Once you have these four values defined, we can help you fine-tune the selection based on noise levels, material compatibility, and control methods to find the one perfect pump for your device.

The Four Key Selection Parameters

| Specification | What It Means | Why It's Critical for Medical Devices |

|---|---|---|

| Vacuum Level (-kPa)11 | The maximum negative pressure the pump can create. | Must be strong enough for the task (e-g, NPWT needs -80 kPa). |

| Flow Rate (L/min) | The volume of air the pump can move per minute. | Determines how quickly a task is done (e.g., clearing an airway). |

| Power Consumption (W)12 | The amount of electrical power the pump uses. | Critical for battery life in portable and wearable devices. |

| Lifespan (Hours) | The number of hours the pump can run reliably. | Ensures the device meets its expected service life without needing repairs. |

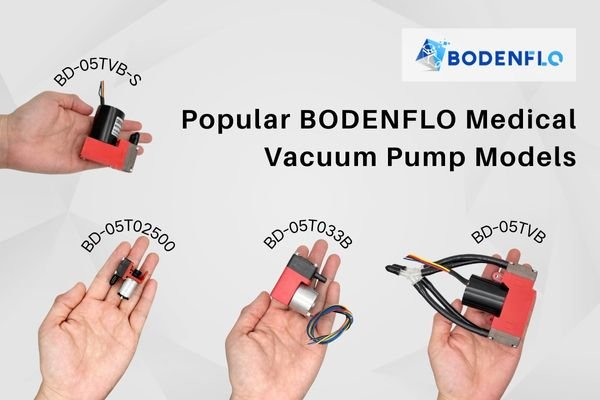

Which BODENFLO Pumps are Popular for Medical Devices?

Theory is helpful, but seeing real-world examples makes selection easier. Sifting through catalogs to find a starting point for your design can be time-consuming and confusing.

Here are some of our best-selling models. They range from ultra-low power pumps for wearables to high-performance, versatile pumps for complex diagnostic machines, providing a proven solution for nearly any medical application.

I often recommend these four models to engineers as a starting point. The BD-05T02500, with its incredibly low 0.5W power draw, is perfect for tiny, battery-powered health monitors. For more robust handheld devices, the BD-05T033B offers a great balance of performance and a long-life brushless motor. When more power is needed for desktop analyzers, the BD-05TVB-S delivers higher flow and deeper vacuum. Finally, the BD-05TVB is our high-performance problem-solver; its unique ability to be connected in series for a deep -90kPa vacuum or in parallel for a high 7.2L/min flow makes it incredibly versatile for the most demanding applications.

Popular BODENFLO Medical Vacuum Pump Models

| Model | Voltage Range | Max Flow | Max Negative Pressure | Motor Type | Key Feature |

|---|---|---|---|---|---|

| BD-05T02500 | 1-5V | up to 550 ml/min | -45 kPa | DC Brushed | Ultra-low power (0.5W) for wearables |

| BD-05T033B | 12V/24V | 2-3 L/min | -55 kPa | DC Brushless | Long life, balanced performance |

| BD-05TVB-S | 12V/24V | 4.6 L/min | -70 kPa | High-end Brushless | High performance for desktops |

| BD-05TVB | 12V/24V | 7.2 L/min (Parallel) | -90 kPa (Series) | DC Brushless | Maximum versatility and power |

Conclusion

A medical vacuum pump’s purpose is to provide controlled, reliable suction. Understanding the key applications, standards, and specifications ensures you choose the right pump for safe and effective patient care.

-

Learn about the mechanisms and benefits of Negative Pressure Wound Therapy to enhance patient healing and care. ↩

-

Explore this link to understand the latest techniques and standards in diagnostic sampling, ensuring accuracy and reliability. ↩

-

Exploring the impact of sub-atmospheric pressure can enhance your knowledge of NPWT effectiveness and patient recovery. ↩

-

Understanding pump reliability is crucial for effective NPWT therapy, ensuring patient comfort and treatment success. ↩

-

Understanding high flow rate is crucial for optimizing pump performance in various applications. ↩

-

Explore the significance of surgical smoke evacuators in protecting health and safety in operating rooms. ↩

-

Explore this link to understand the critical role of IVD applications in ensuring accurate diagnostic results. ↩

-

Learn about biocompatible components and their importance in patient safety and device efficacy. ↩

-

Explore this link to understand how diaphragm pumps enhance safety and efficiency in medical settings. ↩

-

Learn about biocompatibility to see how it ensures patient safety and device effectiveness in healthcare. ↩

-

Understanding vacuum levels is crucial for ensuring the effectiveness of medical devices like NPWT. ↩

-

Exploring power consumption helps in optimizing battery life for portable medical devices. ↩