Do you find yourself puzzled by the increasing significance of micropumps in modern technology? Perhaps you're a procurement officer looking to understand this pivotal component better. Maybe you're an engineer, keen to integrate micropumps in your next big project. Wherever you come from, the fascination around micropumps is real and relevant.

The purpose of a micropump is to offer precision and control in moving small volumes of fluid—be it liquid or gas—across various industries and applications. This workhorse can be particularly beneficial when size, accuracy, and operational efficiencies are key considerations.

The evolving technology of micropumps has disrupted industries far and wide. Keep reading as we dive deeper into the multifaceted roles of micropumps.

Why is Size Important for Micropumps?

The importance of size in micropumps cannot be overstated. In an era where miniaturization is more than just a trend, but a necessity for technological advancements, the small footprint of micropumps becomes incredibly significant. The smaller size directly translates into multiple benefits, making these devices a go-to choice for many applications where space and weight are at a premium.

Size is crucial for portability. In the medical sector, for instance, portable devices like insulin pumps or wearable drug delivery systems must be lightweight and unobtrusive. The small size of micropumps allows these devices to be worn comfortably by patients, thereby facilitating better health management without impeding daily activities.

When integrated into compact systems, such as lab-on-a-chip devices, the diminutive size of micropumps helps in maintaining the system’s overall compactness. This is particularly vital in point-of-care diagnostic equipment or portable environmental monitoring systems, where the device's effectiveness hinges on its ability to be conveniently transported or stored.

In industrial applications, space is often at a premium. Compact micropumps can be integrated into larger systems without requiring substantial design alterations. This is especially beneficial in complex assemblies like chemical reactors or fluidic control systems in manufacturing setups.

What Are the Key Industries Leveraging Micropumps?

Micropumps have evolved as essential components in a variety of sectors, and their utility is ever-growing. Given their capabilities for precise fluid handling, it's not surprising to see them integrated into diverse industrial applications.

Healthcare

In healthcare, micropumps are often used in devices for controlled drug delivery, such as insulin pumps. These pumps provide a constant supply of medication, making life easier for diabetics. They're also used in other therapeutic technologies and clinical chemistry.

Environmental Science

In the field of environmental science, micropumps assist in water quality testing and air sampling. They're ideal for remote data collection, offering a reliable means for monitoring pollutants and analyzing samples.

Lab Automation

Micropumps are integral to the world of lab automation. They help in the distribution and mixing of minute volumes of reagents, which is essential in applications like DNA sequencing or microfluidic analysis.

Industrial Manufacturing

These pumps find roles in a multitude of manufacturing processes. For example, they're utilized for dosing and mixing chemicals in water treatment plants, ensuring a consistent and safe supply.

Consumer Electronics

In the consumer electronics sector, micropumps contribute to cooling systems in computers and other devices. Their small size and efficiency make them particularly beneficial in these applications.

Automotive Industry

Fuel cells in modern vehicles often require micropumps for proper circulation of fluids. They ensure that the fuel cell systems operate at peak efficiency.

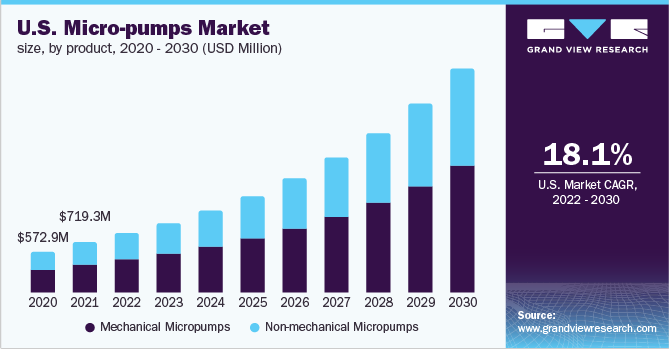

With micropump technology continually evolving, it's only a matter of time before they find roles in even more industries. Recent studies on global micropump usage underline the increasing adoption and diversification of these devices, showcasing a promising trend for the future.

How Do Micropumps Differ from Traditional Pumps?

Traditional pumps, whether they're centrifugal or positive displacement types, have been engineered to handle large volumes of fluids. These are the go-to devices for applications like irrigation, drainage, and industrial fluid management. However, they lack the finesse required for handling minute quantities or for applications that demand precise control.

Micropumps, on the other hand, are designed to specialize in the exact opposite. They are ideal for managing extremely small volumes of fluid with high accuracy.

Precision and Control

Micropumps excel in applications requiring meticulous control, such as drug delivery systems in medical devices or microfluidic experiments in laboratories.

Size and Efficiency

The compact design of micropumps makes them highly efficient in terms of energy consumption and space, which is not the case with their larger counterparts.

Material Compatibility

Micropumps are often made from materials compatible with sensitive fluids, such as biological samples, which is usually not a consideration in traditional pumps designed for more robust industrial applications.

Cost-Effectiveness

While traditional pumps may have lower upfront costs for high-volume tasks, micropumps offer cost-efficiency for tasks requiring precision, as they minimize waste and improve accuracy.

Given these key differences, it's clear that micropumps have distinct advantages in specific applications where traditional pumps simply can't compete.

What Role Do Micropumps Play in Healthcare?

The world of healthcare is continuously evolving, and micropumps have emerged as indispensable tools in this landscape. They serve as the backbone of many critical applications, from drug delivery to diagnostics.

In healthcare, micropumps are fundamentally changing how treatments are administered and how diagnostics are performed, ensuring greater precision and reliability.

One of the most prominent roles of micropumps is in controlled drug delivery systems. Whether it's insulin pumps for diabetics or chemotherapy drug infusion, micropumps ensure that the right amount of medication is administered at the right time. Their precision is vital in avoiding overdoses and ensuring effective treatment.

In diagnostic equipment, miniature liquid pumps are crucial for fluid handling, especially in devices like blood analyzers. They make it possible to process minute volumes of biological fluids, which is essential for quick and accurate diagnosis.

Moreover, micro pressure pump and vacuum pump small size makes them perfect for integration into portable or wearable medical devices. These devices are increasingly used for real-time monitoring and treatment, making healthcare more personalized and accessible.

To sum up, micropumps play a multifaceted role in healthcare. Their precision, reliability, and compatibility with various devices make them an invaluable asset in modern medical practices.

Why Are Micropumps Crucial in Environmental Monitoring?

Environmental monitoring has never been more critical than in our current era, marked by rapid industrialization and environmental degradation. Micropumps are rising to the occasion as key enablers in the technology used for these monitoring efforts.

Micropumps play a pivotal role in collecting, transferring, and analyzing samples in environmental monitoring systems, thus providing accurate and timely data for decision-making.

The first aspect to consider is their precision in fluid control, crucial for accurate sampling in air and water quality monitoring devices. They can handle very low volumes of liquid, allowing for more efficient and precise measurements. Their operational accuracy ensures that the collected data represents true environmental conditions, which is crucial for regulatory compliance and public safety.

In gas detection systems, miniature sampling pumps help in pulling in air samples for real-time analysis. Their compactness and low energy consumption make them ideal for field deployments, even in remote or hazardous locations. The mobility of systems that incorporate micropumps is a major advantage in environmental monitoring, allowing for flexibility and wider coverage.

Micropumps' capabilities—precision, reliability, and portability—make them indispensable in the field of environmental monitoring. Their role in facilitating better and more efficient data collection is vital for keeping a pulse on our planet's health.

Are Micropumps Suitable for Industrial Use?

In industrial settings, reliability and efficiency are not just buzzwords; they're essential requirements. As miniature technology advances, micropumps have proven to be robust contenders for various industrial applications.

Absolutely, micropumps are not only suitable but often essential for industrial use due to their high precision, reliability, and compact form factor.

- Micro pumps are known for their accuracy in fluid control, which is invaluable in sectors like chemical processing and manufacturing. The ability to precisely manage tiny volumes of liquid can be a game-changer in systems requiring exact dosages or mixing ratios.

- The robust construction of industrial-grade micropumps ensures long-lasting performance even in harsh environments. Many are designed to be chemical-resistant and can operate under extreme temperature ranges, making them adaptable to various industrial conditions.

- The compact size of micropumps allows them to integrate seamlessly into existing systems without requiring extensive modifications. This is a huge advantage in industrial settings where space can be at a premium and the cost of altering existing infrastructure can be prohibitive.

In summary, micropumps offer a trifecta of precision, durability, and compactness that makes them incredibly suitable for industrial use. Their versatile and reliable nature ensures they meet the rigorous demands of industrial applications.

What About Lab Applications?

Laboratories are hubs of precision, requiring equipment that meets stringent standards for accuracy and reliability. In this context, micropumps are not just suitable, they are indispensable.

Indeed, micropumps are absolutely crucial in lab applications. Their ability to provide precise control over fluid volumes is essential for a variety of experiments and processes.

- In lab applications such as DNA sequencing, cell culture, and microfluidic systems, the level of precision afforded by micropumps is unmatched. This is particularly vital in experiments where even a small deviation can lead to erroneous results. Their ability to accurately handle small to micro-level fluid quantities ensures that experimental integrity is maintained.

- The compact size of micropump is another advantage in lab settings, which often have space limitations. Their small footprint allows for an efficient use of space, enabling labs to optimize their work areas and potentially fit more equipment and experiments into the same area.

- Many minipumps come with programmable settings, allowing for automated or remote operation. This feature frees up valuable time for researchers to focus on data analysis and other critical tasks, thereby increasing overall lab productivity.

In conclusion, micro pumps are tailor-made for lab applications. They offer the precision, space efficiency, and programmability that are essential for modern laboratories.

How Do You Choose the Right Micropump?

Selecting a micropump for your application is not merely a task; it's an essential decision that can influence your project's success or failure. With an array of choices in the market, how do you ensure you pick the right one?

The key to choosing the right micropump lies in understanding your specific requirements and how they align with the pump's features.

- Assess the flow rate and pressure requirements for your application. Whether you need high flow rates for industrial processes or low flow rates for precise medical applications, understanding these metrics is critical. Make sure to consult product datasheets or engage directly with manufacturers like us at BODENFLO for more details.

- Consider the material compatibility. If you're working with corrosive fluids, you'll need a pump made of materials that can withstand those conditions. Similarly, medical applications often require bio-compatible materials to ensure patient safety.

- Don't overlook the size and weight of the pump, especially if you're working in space-constrained environments like laboratories or medical facilities. Smaller isn't always better; it should align with your needs.

In summary, the right miniature pump for you will meet your flow, material, and size requirements, providing not just a pumping solution, but an asset to your project.

Conclusion

By now, you should have a fairly good idea about the multitude of roles a micropump can play. They are versatile, accurate, and indispensable in a wide range of applications. The key is to identify your specific needs and choose a micropump that fits those requirements.

That's all for now, folks. If you're keen to dive deeper into the world of micropumps, feel free to explore our BODENFLO product range.