Ever find yourself in need of a compact, yet powerful solution for air compression tasks? The problem is real, especially for businesses where space and efficiency are crucial.

A mini compressor is your go-to equipment for various air compression applications in a compact form. These smaller units offer performance comparable to their full-sized counterparts but occupy significantly less space.

Let's delve deeper into what mini compressors are, their applications, and why you might want to consider one for your needs.

Why Choose a Mini Compressor Over Traditional Compressors?

When it comes to choosing a compressor, one may think that bigger is better. However, the industry is shifting towards more efficient and compact solutions without compromising on performance. That's where micro compressors come into play.

Performance Packed in a Small Footprint

Unlike traditional compressors, which can be large and cumbersome, mini compressors offer a small footprint. But don't let their size fool you. They come equipped with advanced technology that allows them to deliver a performance comparable to, and sometimes even exceeding, their larger counterparts.

Technological Advancements

The secret lies in the technological advancements that have been integrated into these mini marvels. From advanced pressure control systems to efficient cooling mechanisms, every aspect is designed to optimize performance.

Portability without Compromise

One of the most striking benefits of mini compressors is their portability. Unlike traditional compressors, which often require a fixed installation, mini compressors can be easily transported and set up, providing flexibility in various applications.

Energy Efficiency

Moreover, their design focus is not just on compactness but also on energy efficiency. Energy consumption is a significant concern in any industrial application, and mini compressors are engineered to consume less power without sacrificing performance.

Direct Current Supply for Unmatched Flexibility

Another feature that sets mini compressors apart is their ability to operate on a direct current (DC) supply. This is a significant advantage in terms of flexibility and ease of integration into various products and systems. While traditional compressors usually require an alternating current (AC) supply and often dedicated electrical installations, mini compressors can easily adapt to the available power supply, especially in mobile or remote applications. The DC supply feature simplifies the integration process, making it more straightforward to include the mini compressor in a wide array of products, from portable medical devices to compact industrial machinery.

What are the Applications of Mini Compressors?

The versatility of mini compressors cannot be overstated. These compact devices have a wide range of applications that extend far beyond the basic functions commonly associated with compressors.

Automotive Use

In the automotive sector, mini compressors are invaluable for inflating vehicle tires, especially in emergency situations where you might be far from a service station. Their compact size allows them to be easily stored in a car's trunk, ready for use when needed.

Medical Equipment

In the healthcare industry, these compressors are often integrated into various medical devices requiring pressurized air. Their small footprint and efficient operation make them ideal for portable oxygen concentrators, nebulizers, and other respiratory care equipment.

Art and Craft

For artists who rely on airbrushing techniques, a mini compressor provides the precise airflow required for detailed work. The device's portability and ease of use also make it a favorite among hobbyists and professional artists alike.

Cleaning Equipment

In the field of cleaning and sanitation, mini air compressors (for example 24V,3A, 6bar, 45L/min) are making their mark by powering high-pressure foam cleaners. These devices utilize the compressor to generate high-pressure foam that covers a larger surface area, requiring less cleaning agent and thereby reducing costs. The foam also clings better to surfaces, providing a more thorough and effective cleaning process. Its efficiency and economical use of cleaning agents make it a popular choice in both industrial and domestic cleaning scenarios.

How Does Size Affect Performance?

In the world of compressors, there's a common misconception that smaller size equates to diminished performance. With advancements in technology, this notion has been effectively dispelled. Mini compressors today are engineered to deliver robust performance, often rivaling their larger counterparts in efficiency and reliability.

Efficiency in a Compact Form

Thanks to cutting-edge materials and smart design choices, modern mini compressors offer high energy efficiency. They are capable of delivering comparable air pressure and flow rates as some of the larger models but do so without consuming excessive power or space.

Smart Technology Integration

Another area where size does not compromise performance is the integration of intelligent controls and sensors. These features allow for precise operation, automated adjustments, and real-time monitoring, ensuring that the compressor performs optimally under varying conditions.

Mini compressors defy the notion that "bigger is always better." They offer an impressive range of capabilities while keeping a compact footprint, making them highly suitable for applications where space and energy efficiency are premium considerations.

What Makes Mini Compressors Cost-Effective?

When it comes to evaluating the cost-efficiency of mini compressors, especially those equipped with brushless DC motors, a holistic approach is essential. Merely considering the initial acquisition cost can be misleading. A thorough financial analysis should also encompass the long-term operating and maintenance expenses, providing a complete overview of cost-effectiveness.

Operating Costs and Energy Efficiency with DC Compressors

Mini compressors, particularly brushless DC air compressors, are engineered for supreme energy efficiency, which directly impacts your utility expenses. These 24V compressors employ state-of-the-art brushless DC motors and optimized aerodynamic design, ensuring maximal output for every watt of electrical input. This remarkable efficiency is not merely an exercise in cost-reduction; it aligns with broader sustainability initiatives by minimizing your carbon footprint.

Reduced Maintenance and Extended Longevity

The relatively lower maintenance costs associated with mini compressors are further optimized in the brushless DC variants. The compact and streamlined construction, usually available in 24V and 24-volt air compressor configurations, minimizes the number of components prone to wear and tear. Consequently, these units require fewer repairs over their operational lifespan. Additionally, the utilization of premium-grade materials in construction augments the equipment's durability, further deferring the capital cost of replacement.

In sum, mini compressors—especially those incorporating brushless DC technology—are a prudent financial investment for numerous applications. They offer compelling advantages in long-term operating and maintenance costs, making them a cost-effective choice that should not be overlooked.

Are Mini Compressors Reliable?

The question of reliability is a pivotal consideration when investing in any piece of equipment, and compressors are no exception. The prevailing perception may suggest that the compact size of mini compressors could compromise their reliability. However, this notion is outdated, as modern engineering advancements have ensured that these units are not only reliable but also often exceed performance and durability expectations.

Advanced Engineering for Consistent Performance

Today's mini compressors are designed with cutting-edge technologies that ensure consistent and robust performance. High-precision components, quality materials, and stringent manufacturing standards result in a reliable unit that can withstand rigorous operational demands. These advances have resulted in mini compressors that offer the same level of dependability as their larger counterparts, making them suitable for a broad range of applications.

Longevity and Durability

When it comes to durability, mini compressors are built to last. They are constructed with materials that resist corrosion and wear, ensuring a longer lifespan. The engineering focus on durability minimizes downtime due to repairs and maintenance, ultimately increasing the equipment’s reliability over time.

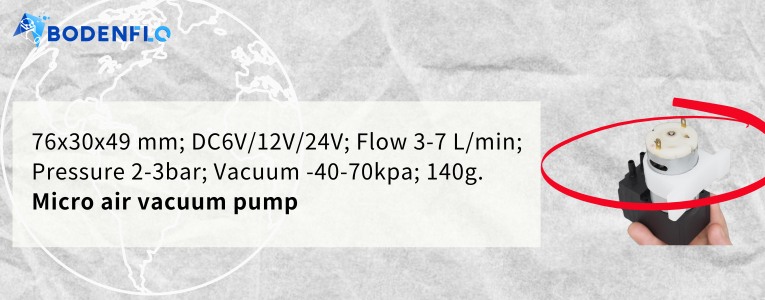

Why Are Some Mini Compressors Also Called Micro Air Pumps?

The terms "mini compressor" and "micro air pump" are sometimes used interchangeably, but it's essential to understand the nuances between the two to appreciate why they might be referred to as the same in certain contexts.

Semantic Overlap

The primary reason for the semantic overlap is the core functionality: both devices move air or gas. They serve similar purposes in various applications such as medical devices, industrial machinery, and consumer goods.

Range of Applications

Both mini compressors and micro air pumps find applications across a similar spectrum of industries. Be it healthcare, automotive, or hobbyist activities, you will find one or both of these devices in use. This broad application base can lead to a blending of terminology.

Specific Needs

In specialized cases, a mini compressor may be referred to as a micro air pump when it is customized to meet the criteria commonly associated with micro air pumps, such as lower pressure and flow rates. For instance, a mini compressor may be configured as a 24v compressor or a brushless dc air compressor to adapt to specific low-pressure needs, making it functionally similar to a micro air pump.

Marketing and Consumer Understanding

Sometimes, the terms are used interchangeably for marketing reasons or to make the product more understandable to a lay audience. Manufacturers may label their mini compressors as "micro air pumps" if they believe it makes the product more accessible or marketable to a specific consumer base.

While mini compressors and micro air pumps have unique features and specific applications, the overlap in their core functionalities and usage scenarios may lead to the two terms being used interchangeably. Understanding the specific needs of your application will guide you in selecting the right device, regardless of the terminology used.

Conclusion

In summary, mini compressors are versatile, efficient, and cost-effective, making them ideal for a wide range of applications. For those looking for reliable and customized mini compressor solutions, BODENFLO offers a range of high-quality, parametrically customizable products designed to meet your specific needs.