Tired of replacing your micro diaphragm pumps? High pressure creates intense heat and stress, causing premature failure. A low-pressure design offers a simple, effective solution that saves you money.

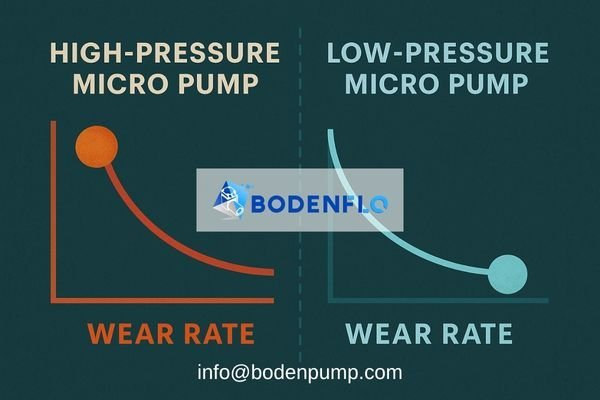

High-pressure micro diaphragm pumps wear faster because they force the motor, diaphragm, and valves to work harder. This increases mechanical stress and generates excessive heat. Switching to a lower-pressure dc diaphragm pump reduces this load, extending its lifespan in continuous-duty applications.

I've seen this issue countless times with clients. A powerful miniature diaphragm pump seems like a good idea, but it often backfires. Let's look at exactly why pushing for high pressure is so destructive and how a smarter approach can save your system. This isn't just theory; it's based on a decade of real-world failures and the engineering solutions that we've proven work time and again.

Why Do High-Pressure Micro Diaphragm Pumps Experience Faster Wear?

You specify a high-pressure diaphragm air pump for its supposed power, but it fails anyway. The problem is the hidden mechanical stress it creates. This constant strain is silently destroying your components.

High pressure increases mechanical load exponentially. It forces the diaphragm to stretch more, puts greater impact on the valves, and makes the motor work harder. This combination of higher stress and friction causes components to fatigue and break down much faster than in low-pressure systems.

The Cascade of Failure from High Pressure

When you demand high pressure1 from a micro diaphragm pump, you're not just asking for a little more work; you're multiplying the forces on every internal component. It's a chain reaction that leads directly to failure. The motor has to pull more current to generate the torque needed to push against the high backpressure2. This extra current creates heat. At the same time, the diaphragm is forced into a longer stroke, causing it to fatigue. The valves must slam shut against a stronger force, leading to accelerated wear. It's a cascade of destructive forces that a low-pressure design avoids.

| Component | Impact of High Pressure (3 bar) | Impact of Low Pressure (1.5 bar) |

|---|---|---|

| Diaphragm | High bending stress, risk of micro-tears | Gentle flex, within elastic limits |

| Valves | High-impact closing, faster wear | Smoother motion, reduced impact |

| Motor | Draws high current, generates excess heat | Draws low current, runs cooler |

| Seals | High compression, accelerated fatigue | Lower stress, longer life |

How Does High Pressure Directly Increase Heat, Torque, and Material Stress?

Your pump feels hot to the touch and then fails. This isn't a coincidence. High pressure directly creates the heat that kills your pump by degrading its core materials from the inside out.

High pressure requires more motor torque, which generates significant heat. This motor heat, combined with the heat from air compression, thermally ages the diaphragm and bearings. Heat is the number one killer because it makes materials brittle and weak, leading to catastrophic failure.

Heat: The Silent Killer of Pumps

Let's connect the dots precisely. To create high pressure, the motor must work harder, increasing its electrical current draw and generating heat—this is basic physics. Simultaneously, compressing air itself generates heat. This creates a "cumulative thermal load" that attacks the pump's most vulnerable parts. The diaphragm, often made of EPDM, FKM, or PTFE,3 begins to lose its flexibility and becomes brittle through a process called thermal aging4. Bearings and connecting rods in the dc diaphragm pump experience higher friction, adding even more heat. I always tell my engineers that if you can solve the heat problem with a diaphragm air pump, you can solve 90% of premature failures. Heat isn't just a symptom; it is the primary weapon that high pressure uses to destroy your equipment.

What Happens When a High-Pressure Pump Runs Non-Stop?

You need your pump to run 24/7, but it keeps failing. Continuous operation magnifies every flaw in a high-pressure design. The system simply can't handle the relentless, unending stress.

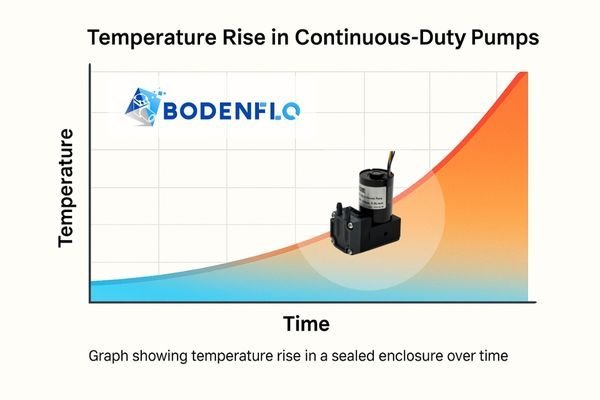

In continuous-duty systems, a high-pressure micro diaphragm pump never gets a chance to cool down. This leads to a steady rise in temperature, accelerating diaphragm fatigue and valve decay. When placed in a sealed box, the heat becomes trapped, causing failures two to three times faster.

The Downward Spiral of Continuous Operation

Imagine running a marathon at a full sprint—you wouldn't last long. That's what you're asking a high-pressure pump5 to do in a continuous-duty application. The temperature rise6 isn't linear; it climbs and climbs until it reaches a point where the materials start to break down. I've seen motor temperature curves that look like a cliff face under heavy, continuous load.

The diaphragm material, constantly flexing under high stress and heat, develops fatigue cracks. The valve plates lose their stiffness, causing them to seal poorly. This drop in performance means the pump has to work even harder to maintain pressure, which generates even more heat. It's a vicious cycle that ends in complete failure. When you put that same pump in a sealed box, you're essentially putting it in an oven. Failure is no longer a question of "if," but "when."

Case Insight: What Went Wrong in Our Client’s Aeration System?

A client's pumps kept failing. They were powerful, so what was the problem? The issue wasn't the pump's quality but a mismatch between its design and the specific application demands.

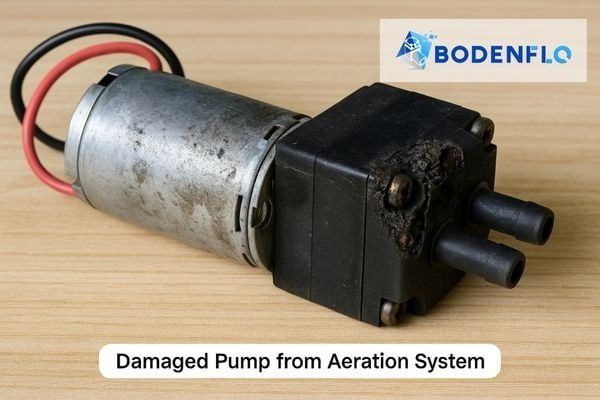

We had a client use a 3 bar, 4 L/min pump for 12-hour continuous aeration inside a sealed box. The high pressure and lack of ventilation caused extreme heat buildup, pushing internal temperatures above 60°C. This cooked the motor and diaphragm, leading to repeated, predictable failures.

An Engineering Diagnosis of a Predictable Failure

I remember getting the call. The client was frustrated because they had bought what they thought was a robust, high-performance pump7, yet it was failing within a couple of months. As soon as they mentioned it was running for 12 hours straight inside a sealed enclosure, I knew what the problem was. They sent us a failed unit. The diaphragm was brittle and cracked, with heat discoloration on the motor windings. Their system required aeration, a low-pressure task, but they had chosen a high-pressure micro diaphragm pump. This combination—a high-revving engine for a low-speed job, trapped in a hot box—was a recipe for disaster. The pump was destroying itself with its own heat. We immediately recommended a switch to a low-pressure model8.

Which BODENFLO Micro Diaphragm Pumps Are Built for Longevity?

You need a reliable pump for continuous duty. The solution is choosing a model engineered specifically for low-stress, long-life operation. These pumps prioritize efficiency and thermal management over raw pressure.

BODENFLO offers several low-pressure, high-flow micro diaphragm pumps designed for 24/7 reliability. By using efficient coreless and brushless motors, these models run cooler and last longer, making them ideal for continuous-duty systems.

Our Top Pumps for Continuous-Duty Applications

Based on the principles we've discussed, here are some of our best-performing miniature diaphragm pump models for long-life applications. They are designed to operate efficiently under low-pressure loads, minimizing heat and wear. Notice the focus on efficient motor types9 (coreless, brushless) and modest power consumption, which are key indicators of a design built for endurance. These models are the direct result of our experience in solving the exact high-pressure failure modes detailed in this article.

| Model | Voltage | Max Flow | Max Pressure | Motor Type |

|---|---|---|---|---|

| BD-05T01530 | 1V~4V (3.3V) | 530 ml/min | +44 kPa | Brushed |

| BD-05T01.51000EP | 1V~4V | 1 L/min | +50 kPa | DC Coreless |

| BD-05T01.52000B | 5V | 2 L/min | +50 kPa | DC Brushless |

| BD-05TVB-S | 12/24V | 4.6 L/min | +1~1.5 Bar | DC Brushless |

What’s the Final Engineering Rule for Selecting Pressure Rating vs. Lifespan?

If there is one thing to take away from this, it's a simple, unbreakable engineering rule: for diaphragm pumps, as pressure goes up, lifespan goes down. They are inversely proportional.

The relationship is clear: Pressure ↑ = Torque ↑ = Heat ↑ = Lifespan ↓. For long-life systems, prioritize lower pressure and better ventilation over a high-pressure rating. "Pressure headroom" is far more valuable than a high maximum pressure spec.

"Headroom" Beats "Rating" Every Time

When selecting a micro diaphragm pump, don't be captivated by a high maximum pressure rating. That number often represents a condition the pump can only sustain for a very short time before it overheats. A much more important metric is what I call "pressure headroom"—the safety margin between your system's actual working pressure and the pump's maximum rated pressure.

For long-life systems, you want that headroom to be as large as possible. If your system needs 0.4 bar, don't choose a 0.5 bar pump. Choose a 1.0 bar pump and run it at 0.4 bar. By de-rating the pump, you are operating it in its comfort zone, dramatically reducing heat and stress. For truly intermittent, high-pressure tasks, a piston pump might be a better design choice. But for continuous-duty diaphragm pumps, less pressure is always more life.

Conclusion:

Lowering a pump's pressure load directly reduces heat and mechanical wear, leading to a more stable and reliable system that lasts for thousands of hours instead of hundreds.

BODENFLO offers customized low-pressure, long-life micro diaphragm pumps for continuous-duty OEM systems. Contact info@bodenpump.com for technical support.

-

Understanding the effects of high pressure can help you optimize pump performance and prevent failures. ↩

-

Exploring the effects of high backpressure will provide insights into pump performance and maintenance strategies. ↩

-

Understanding these materials is crucial for selecting the right diaphragm for pump applications, enhancing durability and performance. ↩

-

Exploring thermal aging will help you grasp its impact on pump materials, leading to better maintenance strategies. ↩

-

Understanding the impact of continuous operation on high-pressure pumps can help prevent costly failures and improve efficiency. ↩

-

Exploring the relationship between temperature rise and pump performance can provide insights into maintenance and operational strategies. ↩

-

Explore this link to understand the advantages of high-performance pumps and how they can enhance efficiency in various applications. ↩

-

Discover why a low-pressure model might be the ideal choice for your system, ensuring longevity and optimal performance. ↩

-

Learn about efficient motor types to enhance your knowledge on pump performance and energy savings. ↩