Are you confused by pump specifications? Choosing the wrong pump can stall your project, forcing costly redesigns and delaying your product launch. It’s a common engineering pitfall.

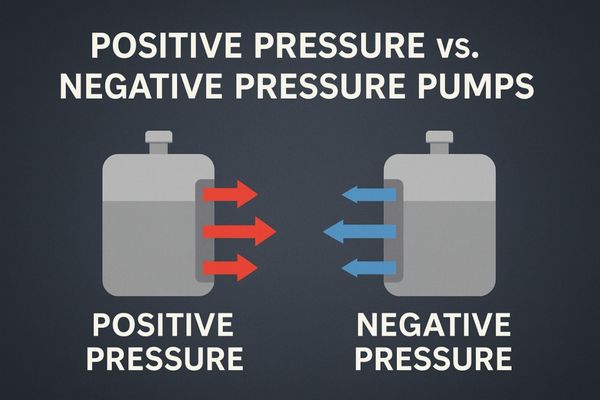

The difference is simple: a positive pressure pump pushes fluid out, creating pressure higher than the surroundings. A negative pressure pump (or vacuum pump) pulls fluid in, creating a pressure lower than the surroundings. It's a matter of pushing versus pulling.

In my years as a product manager at BODENFLO, I've seen brilliant designs get sidelined by this fundamental misunderstanding. I once worked with a team developing a portable air quality monitor. They accidentally specified a pump optimized only for pressure, not vacuum. Their prototype couldn't draw in a consistent air sample, making their sensor data useless. We had to rush a replacement, which cost them two weeks on their timeline. This experience taught me that ensuring my clients understand this core "push vs. pull" concept is the most critical first step in any project. It prevents wasted time and ensures the final product works as intended from day one.

How Does a Positive Pressure Pump Actually Work?

Does your system need to inflate, spray, or move fluid against resistance? Using a pump without enough pushing force will lead to weak performance and system failure.

A positive pressure pump works by taking in a fluid (gas or liquid) and then decreasing the volume of its internal chamber, which forces the fluid out through an outlet port. This action generates pressure higher than the surrounding atmospheric pressure, creating a powerful push.

Think of it like using a bicycle pump. You draw the handle back to fill the chamber with air, then push it down. This act of pushing decreases the chamber's volume, compressing the air and forcing it into the tire against the existing pressure inside. Our diaphragm pumps1 do the same thing, but with a flexible diaphragm moved by a motor. This simple "push" mechanism is the workhorse behind countless applications. My clients use it for everything from atomizing liquids in high-end beauty devices to inflating cuffs in medical blood pressure monitors. The key is always the same: generating enough force to overcome the resistance on the other side.

The Mechanics of Pushing

A motor drives an eccentric cam, which pushes a piston. This piston flexes a diaphragm into a sealed chamber. As the diaphragm moves outward, it reduces the chamber volume, pushing the fluid through an outlet check valve. This creates a powerful, controlled flow.

Key Applications for Positive Pressure

- Medical Devices: Inflating cuffs on blood pressure monitors or powering nebulizers to turn liquid medicine into a mist.

- Automation Systems: Actuating small pneumatic clamps or sorting mechanisms in manufacturing lines.

- Beauty Applications: Powering airbrush systems for cosmetics or skincare treatments.

| Application Example | Why Positive Pressure is Essential |

|---|---|

| Blood Pressure Monitor | To inflate a cuff tightly enough to measure blood flow. |

| Liquid Transfer | To push fluid through tubing and filters. |

| Pneumatic Control | To generate force needed to move small mechanical parts. |

So, What Makes a Negative Pressure Pump Different?

Do you need to collect a gas sample, hold an item with suction, or remove air from a container? Without a proper vacuum, your device will fail to perform these essential tasks.

A negative pressure, or vacuum, pump does the opposite of a pressure pump. It expands the volume of its internal chamber, which draws fluid in through an inlet port. This creates a pressure lower than the surrounding atmosphere, resulting in suction.

I often explain this to clients using the analogy of drinking through a straw. When you expand your cheeks, you create a low-pressure area in your mouth, and the higher atmospheric pressure outside pushes the liquid up the straw. Our vacuum pumps are masters of this "pull" principle. For a client in the environmental sector, we selected a pump that could create a vacuum of -85 kPa2. This was critical for their gas detectors, ensuring they could pull a precise air sample into the sensor chamber, even through long tubes and filters. This pulling force is the entire basis of their product's accuracy. Understanding the required vacuum level is just as important as understanding pressure.

The Art of Pulling

The same diaphragm mechanism is used, but in reverse. As the diaphragm pulls inward, it increases the chamber's volume. This expansion creates a low-pressure zone, and the higher outside pressure pushes fluid in through the inlet check valve. The fluid is then vented out the other side.

Common Use Cases for Negative Pressure

- Gas Analysis: Drawing air or gas samples into environmental monitors or medical diagnostic equipment.

- Robotics: Using suction cups for "pick and place" operations to handle delicate items like circuit boards.

- Medical Suction: Aspirating fluids during medical or dental procedures.

| Application Example | Why Negative Pressure is Essential |

|---|---|

| Gas Analyzer | To pull a consistent, accurate sample into the sensor. |

| Robotic Pick-and-Place | To create a strong suction seal to lift objects. |

| Vacuum Sealing | To evacuate air from a package to preserve its contents. |

Can One Pump Handle Both Positive and Negative Pressure?

Is your device design getting cluttered and expensive with two separate pumps for suction and pressure? This adds unnecessary complexity, cost, and potential points of failure to your project.

Yes, most diaphragm pumps are inherently capable of creating both. The same mechanical action that creates a vacuum at the inlet simultaneously generates positive pressure at the outlet. A single BODENFLO pump can often serve both functions in your system.

This is a design secret I share with clients to give them a competitive edge. One company I worked with was developing a device that needed to first create a vacuum to draw in a liquid reagent, and then use pressure to push it through a sensor. Their initial design had two pumps, a bigger enclosure, and a larger battery. I showed them how a single, slightly larger pump from our lineup could handle both tasks by simply plumbing tubes to both the inlet and outlet ports. This single change reduced their Bill of Materials (BOM) cost3 by 15%, shrank their device footprint by 20%, and simplified their entire assembly process. It’s a perfect example of how understanding the pump's core mechanics can lead to smarter, more efficient engineering.

Leveraging Dual Functionality

A diaphragm pump4 is a displacement pump. For every unit of volume it pulls in through the inlet (creating a vacuum), it must push that same unit of volume out the outlet (creating pressure). By designing your system to use both ports, you can maximize efficiency.

The Project Manager's Advantage

- Reduced BOM Cost: One pump is cheaper than two.

- Smaller Footprint: Saves precious space inside your device.

- Lower Power Consumption: Powering one motor instead of two is more efficient.

- Increased Reliability: Fewer components mean fewer things can go wrong.

| Design Aspect | Two-Pump Solution | Single Pump Solution |

|---|---|---|

| Space Required | High | Low |

| BOM Cost | High | Low |

| Complexity | High (more tubing/wiring) | Low (simplified design) |

| Power Draw | High | Low |

How Do I Choose the Right Pump Specification?

Are you overwhelmed by datasheets full of technical jargon? Choosing a pump based on the wrong spec can lead to poor performance, damaging your device and your company's reputation.

To choose the right pump, focus on three core specifications: flow rate (L/min), pressure (bar or kPa), and vacuum level (-kPa). Match these directly to your application's requirements for optimal performance. Other factors like voltage and weight are also critical.

I always tell my clients, "Don't get lost in the numbers; focus on the job the pump needs to do." The three most important numbers are flow, pressure, and vacuum. Flow rate (L/min) is the speed of your system—how fast it can inflate a cuff or pull a sample. Pressure5 (bar) or vacuum (-kPa) is the strength—the force available to overcome resistance or create suction. A client once chose a pump with very high pressure for a rapid inflation device, but the flow rate was too low. The device worked, but it was too slow for the end-user. We had to switch to a model that balanced both specs. It's also vital to consider voltage for power compatibility and weight, especially for portable devices where every gram counts. Our pumps range from a tiny 18g to more robust 4.7kg models, ensuring a perfect fit.

Matching Performance to Need

First, define your system's requirements. Do you need to move a large volume of air quickly, or do you need to generate high force in a small space? This will guide your selection.

Powering and Fitting Your Pump

Ensure the pump's voltage matches your power source (e.g., a 3V battery vs. a 24V supply). Also, check the physical dimensions and weight to make sure it fits within your device's design constraints.

| Specification | What It Means for Your Application | BODENFLO Range |

|---|---|---|

| Flow Rate6 | How fast your task is completed (e.g., filling a bag, sampling air). | 0.3 – 60 L/min (Air) |

| Pressure | The pushing force available to overcome resistance. | 0.44 – 3.5 bar |

| Vacuum | The pulling force available for suction tasks. | -30 to -100 kPa |

| Voltage | Determines power source compatibility (e.g., battery vs. wall power). | 1V – 24V |

Why is Pump Lifespan So Critical for My Device?

Are you worried about your product failing in the field? A pump with a short lifespan means frequent, costly repairs and unhappy customers, damaging your brand's reputation for reliability.

Pump lifespan, measured in hours, is critical because it directly impacts your product's reliability and total cost of ownership. A longer-lasting pump reduces maintenance, prevents unexpected downtime, and builds customer trust. It's a key indicator of quality and durability.

A pump's lifespan rating isn't just a number; it's a promise of reliability. I worked with a startup making portable medical analyzers. To save on initial costs, they chose a cheap pump rated for only 300 hours. Their devices started failing in less than six months. The cost of recalls and repairs was devastating. We helped them switch to a BODENFLO pump rated for 3,000 hours. While the upfront cost was higher, their total cost of ownership plummeted, and their customer satisfaction soared. When you see a lifespan rating, think about the real-world cost of downtime. A durable pump is an investment in your product's and your brand's long-term health. Our pumps offer lifespans from 300 to over 10,000 hours, so you can match the pump’s durability to your product’s intended use and price point.

Brushed vs. Brushless Motors7

The motor type is the biggest factor in a pump's lifespan. Brushed motors are cost-effective but wear out faster. Brushless motors cost more upfront but last significantly longer, making them ideal for high-use or critical applications.

Matching Lifespan to Application

Does your device need to run 24/7 for five years, or will it be used intermittently for a few months? Aligning the pump's lifespan with your product's expected life cycle is the smartest design choice you can make.

| Motor Type | Typical Lifespan | Cost | Best Use Case |

|---|---|---|---|

| Brushed DC | 300 - 2,000 hours | Lower | Portable devices, intermittent-use products. |

| Brushless DC | 3,000 - 10,000+ hours | Higher | Medical instruments, lab equipment, long-term use. |

Conclusion

Understanding the simple push/pull difference is the key. Choose a pump based on flow, pressure, and lifespan to streamline your design, ensure reliability, and build a successful final product.

📩 Ready to find the right pump for your project?

Contact BODENFLO at info@bodenpump.com for expert guidance and customized pump solutions.

-

Explore this link to understand the mechanics and applications of diaphragm pumps in various industries. ↩

-

Understanding this vacuum level is crucial for ensuring accurate air sampling in gas detectors. ↩

-

Understanding BOM cost is crucial for optimizing product design and reducing expenses. ↩

-

Exploring diaphragm pumps can reveal their efficiency and reliability benefits in various applications. ↩

-

Exploring pressure's role in pump performance can help you choose a pump that meets your specific needs and application. ↩

-

Understanding flow rate is crucial for selecting the right pump for your application, ensuring efficiency and effectiveness. ↩

-

Learn about the key differences between brushed and brushless motors to make informed decisions for your applications. ↩