When it comes to pumps, the question of whether an air pump can be used as a vacuum pump is a common one. As the product manager at BODENFLO, I often encounter this query from our customers and industry professionals. In this blog post, I'll provide you with a comprehensive overview of the possibilities and limitations when using an air pump for vacuum-related applications.

Yes, you can use an air pump as a vacuum! Many air pumps have the potential to generate a vacuum when operated in reverse. This feature makes them versatile tools for various applications. However, it's important to understand the nuances and limitations involved in using an air pump for vacuum purposes, which I'll delve into in the following sections.

Now, let's explore the intricacies of using an air pump as a vacuum and what you need to consider.

Can an Air Pump Efficiently Create a Vacuum?

The question of whether an air pump can efficiently create a vacuum is a fascinating one, rooted in the principles of fluid dynamics and engineering. To answer this query comprehensively, it's essential to delve into how air pumps operate and the unique challenges they face when tasked with generating a vacuum.

Air pumps, often referred to as compressors, are designed primarily to move air from one place to another by creating a flow of air at a higher pressure. In essence, they excel at increasing the pressure of the air they handle. This is a fundamental requirement in numerous applications, from inflating tires to powering pneumatic tools and industrial machinery.

However, creating a vacuum poses a different set of challenges. To generate a vacuum, we need the opposite effect—lowering the pressure inside a closed space. At first glance, this seems contrary to the primary function of air pumps. Nevertheless, some air pumps are engineered with versatility in mind.

Certain types of air pumps possess the unique capability to reverse their operation or incorporate mechanisms that enable them to decrease pressure effectively. In doing so, they can create a vacuum efficiently. These pumps are often used in applications that require precise vacuum levels, such as medical devices, laboratories, and industries involved in chemical processing.

Not all air pumps can efficiently create a vacuum, specialized pumps designed for dual functionality can indeed accomplish this task. Understanding the distinctions between various types of air pumps is crucial when selecting the right equipment for specific applications, ensuring optimal efficiency and effectiveness in diverse operational scenarios.

What Types of Air Pumps Can Generate Both Positive and Negative Pressure (Vacuum)?

When it comes to air pumps, we typically associate them with increasing the pressure of the air they handle, which is essential for various applications. However, for specialized tasks requiring vacuum creation, we need a different approach. This brings us to the fascinating world of air pumps that possess the unique capability to generate both positive and negative pressure, commonly known as vacuum.

Positive Pressure Generation

In their primary function, air pumps or compressors excel at increasing the pressure of air. This is achieved by drawing in ambient air and compressing it to a higher pressure, making them indispensable in scenarios like pneumatic tools, inflating tires, or powering industrial machinery. The principle is clear: they pump air in to create pressure.

The Challenge of Vacuum

Creating a vacuum, on the other hand, demands precisely the opposite – lowering the pressure inside a closed space. While this might seem contradictory, some air pumps are designed with versatility in mind. These pumps can reverse their operation or be equipped with mechanisms that allow them to decrease pressure effectively, resulting in the creation of a vacuum.

Types of Air Pumps with Dual Abilities

Reciprocating Piston Pumps: Reciprocating piston pumps, also known as dual-action piston pumps, are engineered to generate both positive and negative pressure. These pumps use a reciprocating piston within a cylinder to create pressure differentials. By adjusting the piston's movement, they can alternate between compressing air (positive pressure) and creating a vacuum (negative pressure).

Micro Piston Pump Resources: https://bodenpump.com/micro-piston-pump/

Rotary Vane Pumps: Rotary vane pumps are another category known for their dual functionality. They feature vanes or blades that rotate within a chamber, creating varying pressures. By adjusting the rotational direction and speed, they can effectively switch between positive and negative pressure generation. These pumps are used in applications like vacuum packaging, where they remove air from containers, extending the shelf life of products.

Diaphragm Pumps: Diaphragm pumps are highly versatile and capable of handling both positive and negative pressure. They consist of a flexible diaphragm that moves back and forth, alternately compressing and expanding the air chamber. This action can be reversed to create a vacuum. These pumps find applications in industries ranging from healthcare, where they power medical devices, to laboratories and chemical processing.

Miniature Diaphragm Pump Resources: https://bodenpump.com/micro-diaphragm-pump/

Scroll Pumps: Scroll pumps are recognized for their efficiency and ability to operate in both modes. They consist of two interleaved spiral scrolls that create and seal off chambers, gradually reducing the volume and generating a vacuum. These pumps play a crucial role in semiconductor manufacturing and research labs, where maintaining specific vacuum levels is essential.

Peristaltic Pumps: Peristaltic pumps use a rotating roller to compress and decompress a flexible tube. This action can generate both positive and negative pressure within the tube, making them suitable for applications such as medical devices and laboratory equipment.

While not all air pumps possess the dual capability of creating both positive and negative pressure, certain specialized types have been engineered to excel in this regard. Diaphragm pumps, rotary vane pumps, and scroll pumps are prime examples of versatile equipment that can adapt to a wide range of applications, from maintaining precise vacuum levels in scientific experiments to supporting critical medical procedures. Understanding these distinctions is essential when selecting the right equipment for your specific needs, ensuring efficiency and effectiveness in your operations.

The Role of Check Valves in Air Pumps

One crucial component that enables an air pump to function as a vacuum pump is the check valve. Check valves are one-way valves that allow airflow in one direction while preventing it in the other. In an air pump used for vacuum purposes, the check valve ensures that air flows out of the system but does not re-enter when the pump is reversed.

Check Valves Resoures: https://bodenpump.com/pump-accessories/

The Limitations of Using an Air Pump as a Vacuum Pump

While it's possible to use certain air pumps as vacuum pumps, it's essential to acknowledge their limitations. Air pumps are primarily designed for compression, not for achieving deep vacuums. Therefore, their ability to create and maintain a high level of vacuum may be limited compared to dedicated vacuum pumps.

Moreover, the efficiency of an air pump when used as a vacuum pump may vary depending on its design and specifications. Some air pumps may struggle to achieve the level of vacuum required for specific applications.

Selecting the Right Air Pump for Vacuum Applications

If you're considering using an air pump as a vacuum pump, it's crucial to select the right type and model. Not all air pumps are suitable for this purpose, and choosing the wrong one can lead to inefficiencies and suboptimal performance.

Factors to consider when selecting an air pump for vacuum applications include:

- Type of air pump: Look for air pumps designed to be reversible or suitable for vacuum operations.

- Flow rate and vacuum level: Ensure the pump can achieve the desired vacuum level for your specific application.

- Materials and seals: Check that the pump is compatible with the substances it will be handling in the vacuum chamber.

Applications of Air Pumps as Vacuum Pumps

Despite their limitations, air pumps used as vacuum pumps find applications in various industries. Some common uses include:

- Vacuum packaging: Air pumps can be used to remove air from packaging to extend the shelf life of food products.

- Laboratory equipment: In some laboratory setups, air pumps are used for basic vacuum operations.

- Pneumatic systems: Certain pneumatic systems may employ air pumps to create a vacuum when needed.

Conclusion

In conclusion, the versatile capabilities of certain air pumps to operate in reverse and generate vacuum conditions provide a valuable option for various applications. However, it's essential to recognize that air pumps have inherent limitations in comparison to dedicated vacuum pumps, especially for critical vacuum tasks or deep vacuums.

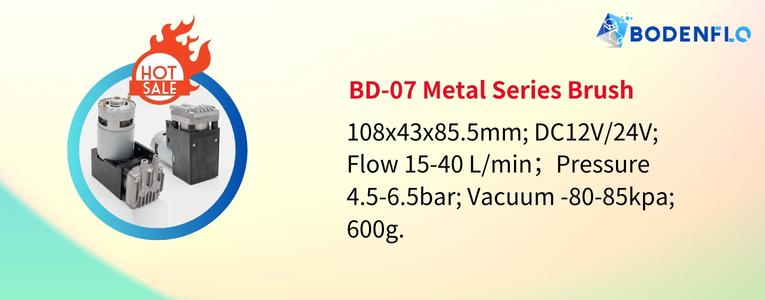

When considering whether you can use an air pump as a vacuum, it's imperative to make a well-informed decision based on your specific vacuum requirements. For BODENFLO, as a leading manufacturer of high-flow miniature vacuum air pumps, we offer a range of specialized solutions to meet diverse needs, including both air and vacuum applications.

If you're seeking reliable and efficient pumps for your operations, we invite you to explore our product offerings. Our expert team at BODENFLO is always ready to assist you in selecting the most suitable pump for your unique needs. Make the right choice and optimize your processes with BODENFLO's high-quality pumps.

Contact us today to discuss your air and vacuum pumping needs, and let us assist you in achieving peak efficiency in your applications.